The National Day holiday is approaching, and in order to avoid equipment performance degradation or malfunction caused by prolonged downtime during the holiday, meticulous maintenance work is required. Evermi is sending this shutdown maintenance guide to all customers and friends. Please keep it safe!

1、 Safety warning before maintenance

Hanging label: Before maintenance, it is necessary to hang a warning sign in a prominent place on the equipment that reads "Under maintenance, do not start".

Personnel protection: Operators are required to wear protective tools such as gloves and masks.

2、 Cleaning of work area

Clean the workbench, bed, guide rails and other parts that are prone to cutting and oil stains, ensuring that there are no residues.

3、 Core component maintenance

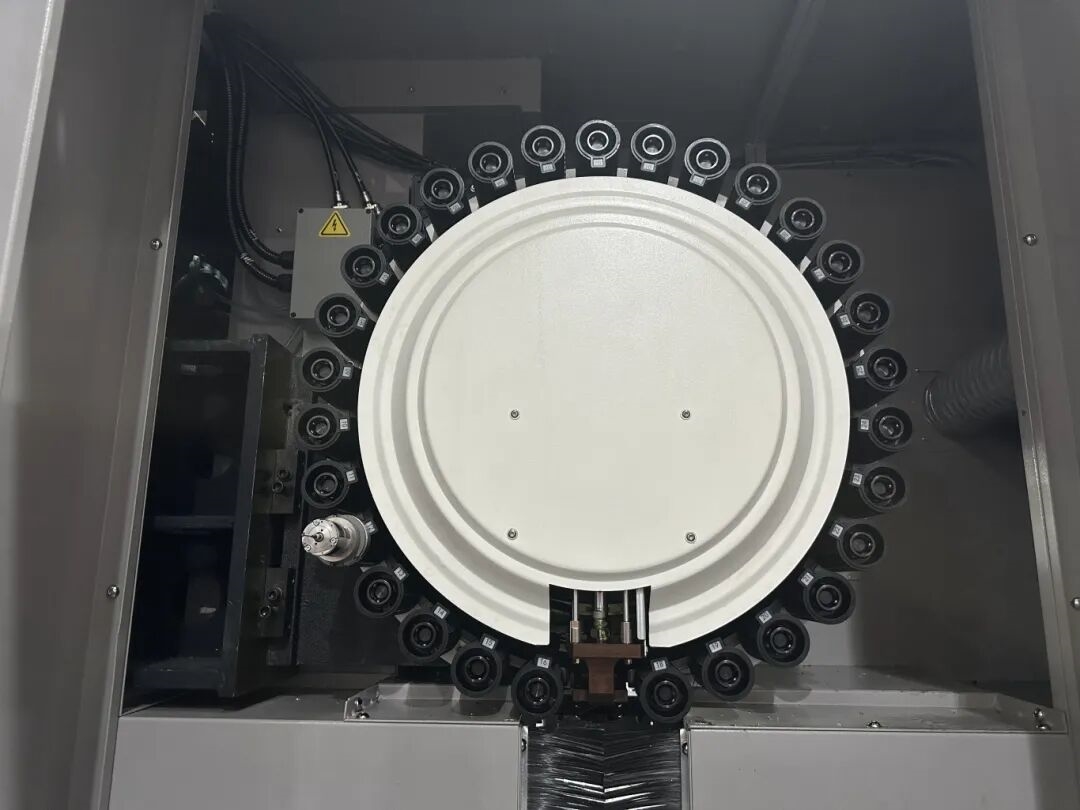

Core components such as the motion axis, tool magazine, and spindle need to be cleaned and lubricated according to specifications to ensure precise operation after the holiday.

1. Clean and lubricate the motion axis

The X \ \ Y \ \ Z axis needs to be cleaned and lubricated to prevent chip residue from affecting accuracy.

2. Maintenance of Cutting Tools and Tool Storage

Remove all knife handles, clean them, and apply oil to prevent rust.

Clean the interior of the knife magazine, inspect the transmission components of the knife magazine, and apply grease for lubrication.

3 Spindle Cleaning and Protection

Clean the spindle taper hole, remove chips and oil stains, apply oil and seal with cling film to prevent dust from entering.

Do not use an air gun to clean the inner hole of the spindle to prevent damage.

4、 Auxiliary system maintenance

Clean the iron slag and cutting fluid from the water tank, rinse the water tank and dry the motor and water pump.

Check the oil cooler and air conditioning filter, clean the dust in the electrical cabinet, and place desiccants.

5、 Data backup and security check

Record the zero point and mechanical coordinate position of the machine tool, and backup important data.

Check the machine tool cables, electrical components, and ensure that there is no damage, looseness, or rust.

6、 Precautions

Before stopping the machine, ensure that all axes have returned to their original positions to avoid prolonged exposure to extreme positions.

Special protective plugs are installed on the spindle taper hole, and the operation panel is sealed with transparent plastic film.

Proper maintenance of five axis equipment during long holidays can safeguard production accuracy and extend equipment lifespan. Wishing everyone a happy National Day and efficient resumption of equipment work after the holiday!