-

E-mail

liuhaijunsh@yeah.net

-

Phone

13661760867

-

Address

101, Building 2, No. 55 Jingbian 1st Road, Balidian Town, Wuxing District, Huzhou City, Zhejiang Province

Nazai Intelligent Technology (Zhejiang) Co., Ltd

Founder of Nazai: Liu Haijun

Date: 2025-11-20Read: 4

In the autumn of 2000, the wind in Shaodong, Hunan was wrapped in the fragrance of osmanthus flowers. As it crossed the bluestone road, it gently lifted the hem of the young Liu Haijun's clothes. At that time, no one knew that this young man from Hunan, who grew up smelling the fragrance of osmanthus flowers, would plunge into a machine tool workshop filled with the smell of engine oil in the future. Starting as an apprentice cleaning machines, he would let the faint light of "Made in China" gradually spread like wildfire between gear teeth; It will also blend the softest warmth of the world into the folds of friendship and public welfare.

01

He used 'stupid kung fu' to feel the 'heartbeat' of the machine tool

In his early days in the workplace, Liu Haijun's world was made up of the smell of engine oil, metal shavings, and the cold and hard shells of machine tools. He walked into a foreign-funded enterprise and faced the interviewer's question of "which department do you want to go to", he resolutely chose the most tiring equipment department and took the initiative to undertake the dirtiest machine cleaning work in the department.

When others are slacking off with a cloth, he sees it as a shortcut to 'understanding machines'. Fingertips repeatedly caress the patterns on the machine tool casing, as if touching a precious treasure; The oil stains were hidden in the gaps of the parts, so he used a small brush to clean them up bit by bit, while also seeing the layout logic of the internal parts. When the machine tool was wiped so hard that it could reflect a human figure, he leaned close to the master and stared at the machine without blinking: which screw to tighten first, how many turns to turn the wrench, how to align the guide rail, even the master's casual remark of "leaving half a millimeter of gap" was recorded in his notebook.

This' stupid kung fu 'has not been let down. From a newcomer who only knows how to pass tools, to someone who can assist in installing machines, and then to independently shoulder the burden of equipment assembly, his position is like a gear on a machine tool, steadily advancing with his skills. Under the incandescent lamp in the workshop, he had already quietly engraved every pattern and position of every screw on the machine tool into his heart - this period of crawling and rolling was not hard work, but his first "ballast stone" in the industry, which firmly supported his later technical confidence.

02

The spark of 'domestic machine tools' ignites a prairie fire in the heart

When Liu Haijun left the foreign-funded enterprise, his hands had already been stained with countless machine tool oil stains, and his eyes had gained a sense of certainty. When faced with the imported grinding machine that came from abroad, he had already shed the initial awkwardness, and his eyes had a sense of determination and seriousness. Over the course of ten years, he immersed himself in imported machine tools. With a willingness to endure hardship and a love for research, he gradually improved step by step. With the advancement of technology, the models he came into contact with expanded from basic models to various precision equipment. With more parts touched by his fingertips, his inner question became increasingly clear: "Why can't we Chinese make such precision machine tools

In Shanghai in 2015, the maker wave was booming, and Liu Haijun, with the seed of "never give up", founded Nazai - the four words "replace imports", which he wrote on the top of the office whiteboard with a black pen and became the gene of the enterprise. In the summer of 2018, the C818 five axis grinder emerged. The name of this machine tool contains two intentions: one is the national spirit of benchmarking against the C919 aircraft, and the other is the obsession with "Made in China"; In 2019, a final assembly factory was built in Wanma Industrial Park, Huzhou, with a complete industrial chain from research and development to after-sales service. This young enterprise quickly became a "national high-tech enterprise" and made a breakthrough in the field of domestic CNC tool grinding machines.

03

The 'New Fuel' in the Classroom

As the loaded machine tools began to enter the workshops of more and more customers, Liu Haijun made an unexpected decision: to return to the classroom. He knows that in order for domestic machine tools to go far, they cannot rely solely on "hand feel", but also need systematic technical theory and management logic to support them.

From 2021 to 2023, in the MBA classes at Xinhua Business School in Hong Kong (Fudan Campus in Shanghai), one can always see his figure taking notes. The logic of modern enterprise management is gradually integrated into the operations he carries; Starting from 2023, in the classroom of the Mechatronics major at Changsha University of Science and Technology, he has once again become the most serious "student" - turning the technical bottlenecks encountered in entrepreneurship into questions in the classroom; Repeatedly verify the practical experience in the workshop with the theories in the textbook. The lights in the classroom, like the machine lights in the workshop, are illuminating his way forward. The knowledge points that were gnawed on eventually became the "new fuel" driving the advancement of payload technology, taking the precision of domestic machine tools one step further to the "micrometer level".

04

Craftsmanship and Temperature

Craftsmanship and Temperature

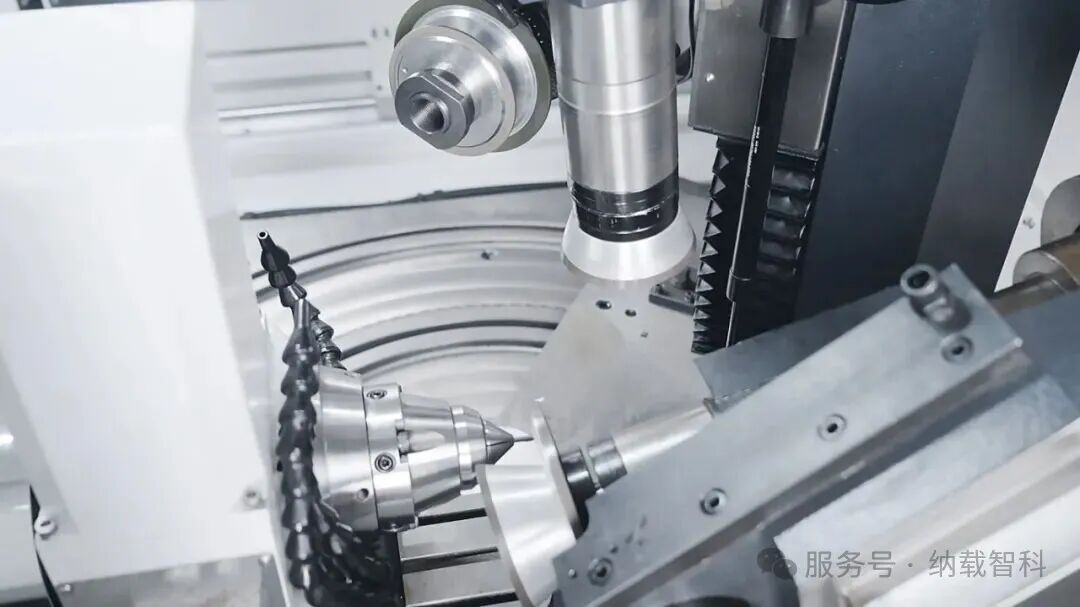

Entering the temperature controlled workshop of the Huzhou factory, there is no dust in the 22 ℃ air, and engineers are busy with assembly. Liu Haijun touched the door panel of the machine tool with his fingertips, his eyes filled with pride: "Imported machines still use worm gears, but we have replaced them with DD direct drive motors, which can achieve accuracy that is only a fraction of a hair. ”Before leaving the factory, each machine tool needs to undergo multiple rounds of calibration with a Renishaw laser detector, and any deviation of 0.001 millimeters needs to be re debugged - this obsession with "accuracy" has enabled the loaded machine tool to achieve the same level of performance as imported machines.

He always said that machine tools should focus on "accuracy" and being a person should focus on "temperature" - the former is the confidence of domestic machine tools, while the latter is the original aspiration of Chinese people.

From the young man holding a cloth in the workshop of a foreign-funded enterprise to the entrepreneur who has supported domestic machine tools today, Liu Haijun's life has never lost the seriousness of "cleaning machines": he respects technology, so he strives for the ultimate precision; Persisting in growth, so willing to return to the classroom at the peak; Gentle to the world, so in the hardcore industrial world, there is a soft human sentiment hidden. This is the appearance of Chinese intelligent manufacturers.