-

E-mail

njwxcnc@163.com

- Phone

-

Address

No. 2 Kaituo Road, Jiangning Economic and Technological Development Zone, Nanjing City

Nanjing Huaxing CNC Technology Co., Ltd

Exhibition Announcement | The 22nd China (Yuhuan) International Machine Tool Exhibition

Date: 2025-10-14Read: 8

Nanjing Huaxing CNC Technology Co., Ltd

Nanjing Huaruixing CNC Technology Co., Ltd

Booth Number: W2 Hall T33

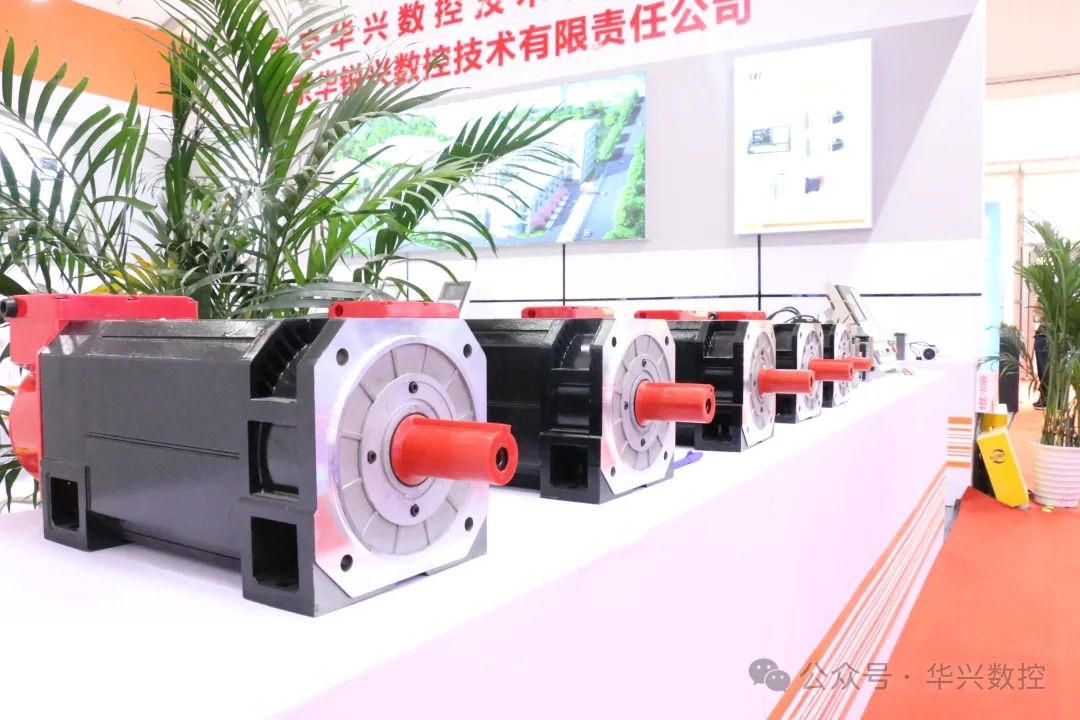

As one of the mainstream CNC system suppliers in China, Huaxing CNC provides a complete set of electronic control products for machine tools, including CNC systems, AC servos, spindle servos, AC servo motors, spindle servo motors, and isolation power transformers. All products are independently designed and produced with high cost-effectiveness and reliability.

Our company is one of the professional manufacturers in China with a full range of CNC supporting capabilities: we have the ability to independently design and produce a full range of products including CNC units, servo units, spindle units, and supporting motors. Annual sales of over 50000 sets.

The CNC system adopts a CPU with independent intellectual property rights to ensure reliable performance and safe supply.

The company has two SMT surface mount production lines, two high-speed stamping lines for motor stator and rotor, one automatic plug-in production line, servo and spindle stator automatic lines, motor progressive die, fully automatic dipping, painting, baking and drying lines, and testing equipment. The annual output of circuit boards is about 400000 pieces, and it has the production capacity of 150000 servo and spindle motors per year. The second phase of the company's factory building has been put into use, with a total area of 25000 square meters.

'High quality, fast, and convenient' is the company's commitment to its vast user base. The company has established more than ten service offices across the country, with nearly 70 employees stationed throughout the country, providing fast services to users nearby

The company has the following after-sales offices:

Ningbo Office, Cixi Office, Taizhou Office, Yuhuan Office, Wenzhou Office, Fujian Office, Yongkang Office, Diankou Office, Shandong Office, Weifang Office, Hunan Office, Hebei Office, Cangzhou Office, Chongqing Office, Jiangsu Office, Henan Office, Hangzhou Office, Shanghai Office

partial products

1 WA-N790XTN/WA-N790XGN 10.4-inch CNC system for turning, milling and grinding machining

WA-N790XTN/WA-N790XGN is our company's newly launched bus based multi axis multi-channel series CNC system. The bus core adopts the 485 bus communication standard and combines our company's independent intellectual property (patent number ZL 2012 1 0150455.2) with a hard core solution. The control cycle is 128us~4ms, and it is matched with our HDV series 2.2kw, 4KW, 6KW, 9KW, 11KW, and 15KW spindle servo units, providing high reliability and cost-effectiveness.

WA-N790XTN, Support CNC system for combined machining of turning, milling and drilling, with multi axis and multi-channel functions, supporting 4-channel and 16 axis parallel machining.

WA-N790XGN, Special CNC system for grinding machines, supporting high-precision jog movement.

2 WA-N750XTN CNC system for turning, milling and grinding machining

WA-N750XTN is our company's newly launched bus based multi axis and multi-channel series CNC system, which supports 16 channel and 48 axis servo control. Open PLC ladder diagram and user macro program programming. The system uses ST company's ARM CPU with a main frequency of up to 400MHz. It is suitable for various machine tools, automatic feeding, synchronous processing of multiple workstations and power heads, dual spindle, dual tool holder, dual head lathe and other mechanical controls that require synchronous and parallel work.

3 WA-N780XTN/WA-N785XTN Multi axis Multi channel CNC System

4 GDX bus type multi in one servo drive

The GDX series bus type three in one driver is a new generation of bus type high-precision, high response combined spindle and feed servo drive product independently developed, designed, and produced by our company.

GDX adopts the POWERLINK industrial 485 bus communication specification, combined with our company's proprietary hard core bus controller (patent number ZL 2012 1 0150455.2), and uses a 1394 interface to interconnect with the upper computer numerical control system. The communication reliability is much higher than similar products such as RJ45. It is an intelligent power device with high integration, complete built-in protection and alarm functions, and high reliability.

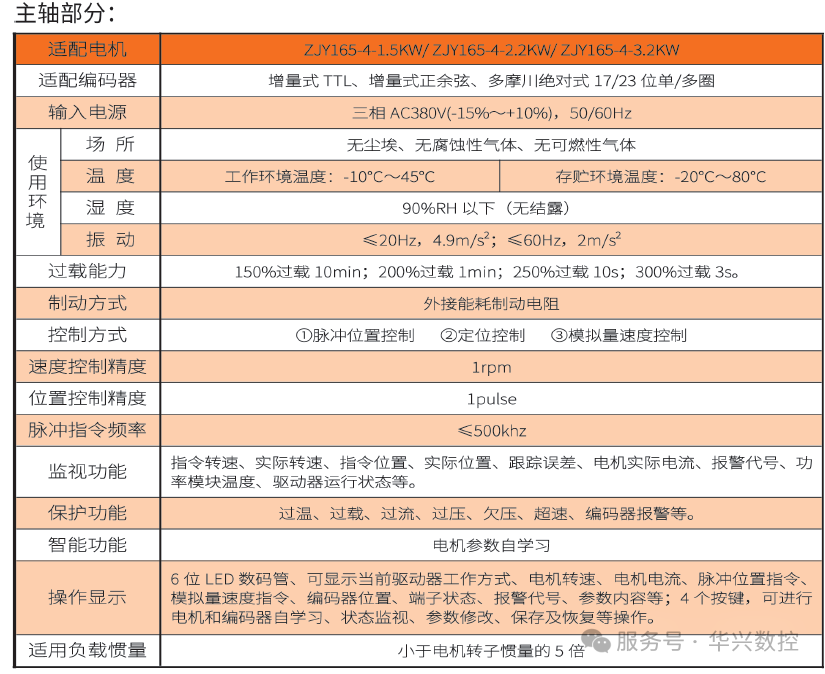

5 HDV series AC asynchronous spindle servo drive

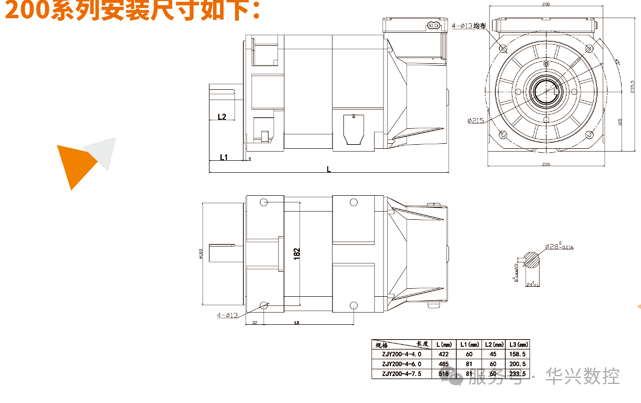

6 AC asynchronous spindle servo motor

7 WA-HMI dedicated truss controller

Can meet various truss applications, with simple and easy to learn programming in Chinese

Equipped with 8 sets of material trays, it can grab and place materials in a single or double tray manner

Equipped with 40 sets of reference points, it can record various points during the movement of the truss

Equipped with 10 safety zones and overcurrent protection to prevent accidental collisions

Adopting an 8-inch LCD screen and supporting Chinese input through touch and button operation

Adopting bus based communication to directly connect servo and external input/output, the output can be directly connected to solenoid valves, reducing cabinet wiring