-

E-mail

njwxcnc@163.com

- Phone

-

Address

No. 2 Kaituo Road, Jiangning Economic and Technological Development Zone, Nanjing City

Nanjing Huaxing CNC Technology Co., Ltd

Core exhibits win market favor, Huaxing CNC Yuhuan Machine Tool Exhibition successfully concludes

Date: 2025-10-27Read: 12

The 2025 Yuhuan Machine Tool Exhibition came to a successful conclusion on October 20th at the Yuhuan Convention and Exhibition Center. As an influential machine tool exhibition in Yuhuan, for more than 20 years, it has not only attracted numerous strong manufacturers from all over the world to participate, but also carried forward Yuhuan's golden signboard as a 'small' specialized and refined 'machine tool production base in China. At this popular industry event, Nanjing Huaxing CNC Technology Co., Ltd. (hereinafter referred to as Huaxing CNC) performed outstandingly, and the exhibits won the favor of on-site buyers.

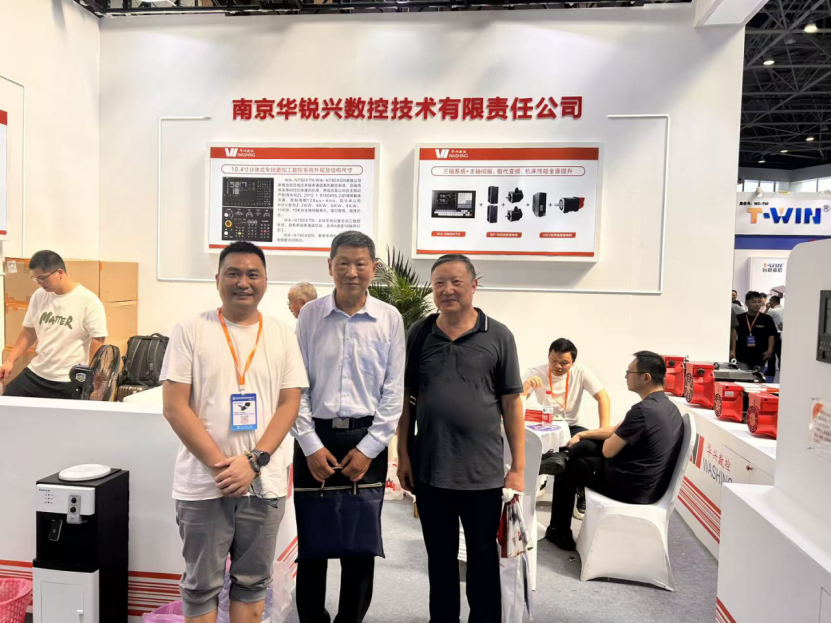

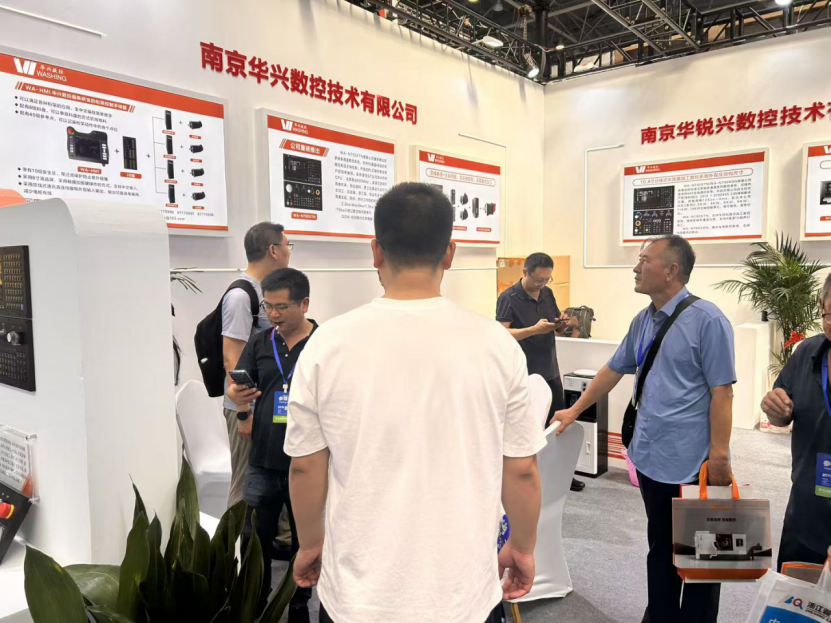

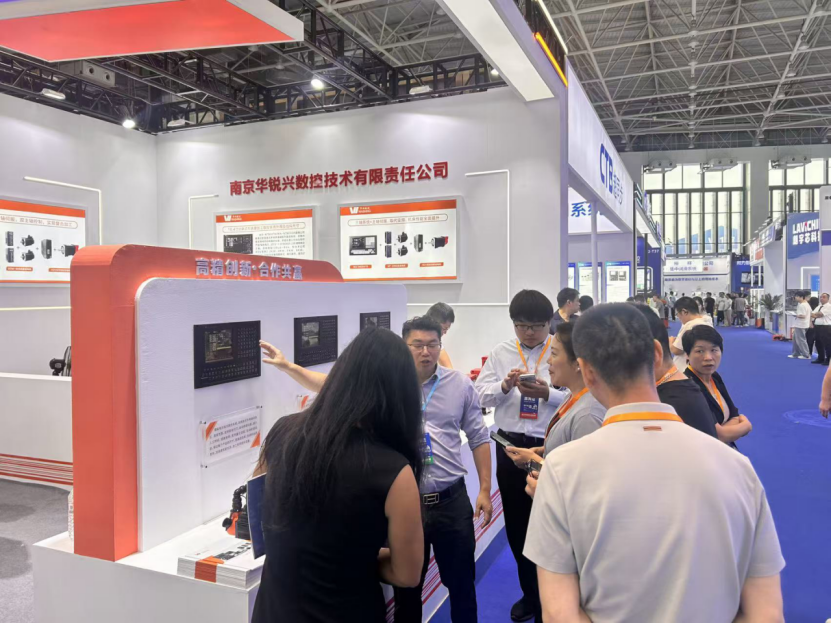

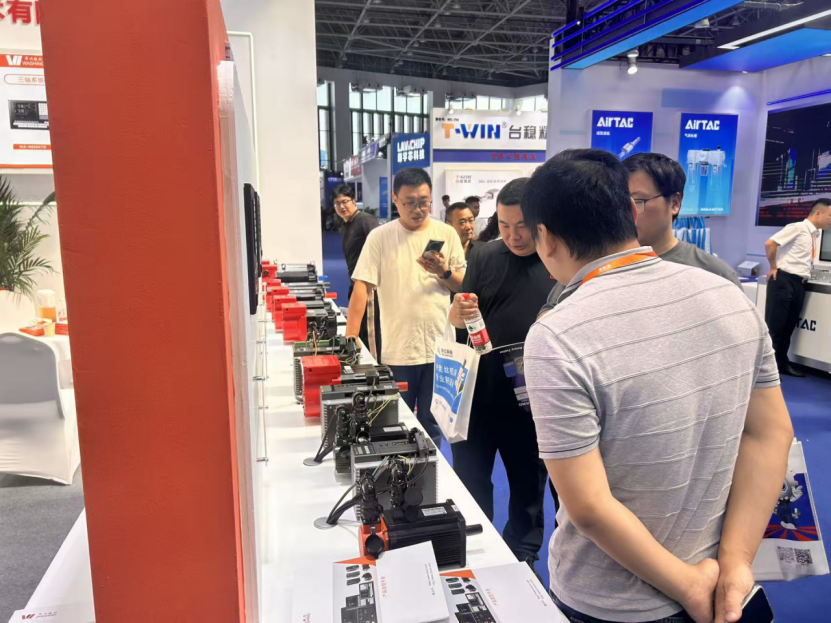

The Huaxing CNC booth is located in Hall W2, T33. The booth continues the consistent red, white, and black color design concept and stands out among the exhibitors. Since the first day of the exhibition, buyers have come to inquire every day, and we have been busy introducing to customers, "said the staff of Huaxing CNC." There were many visitors, including our partners, and multiple cooperation intentions and purchase orders were reached at the exhibition

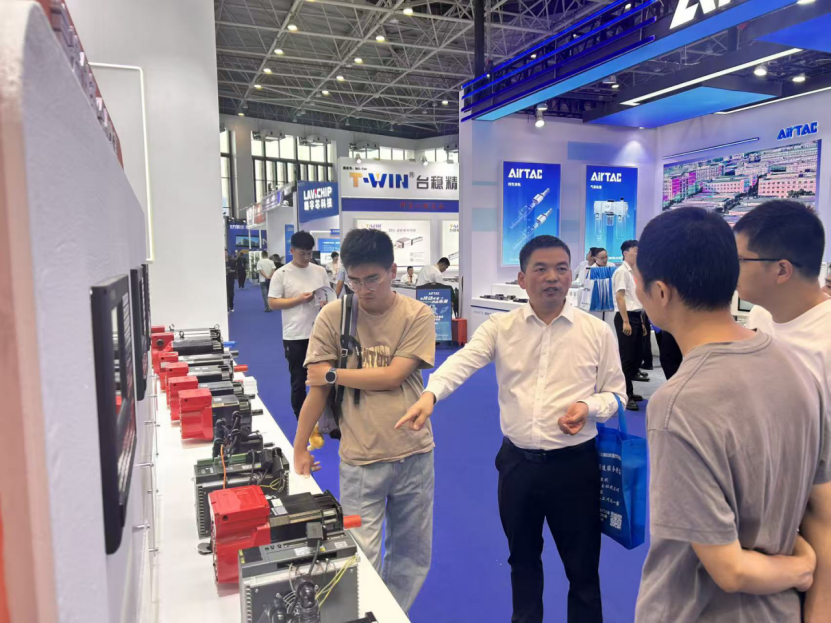

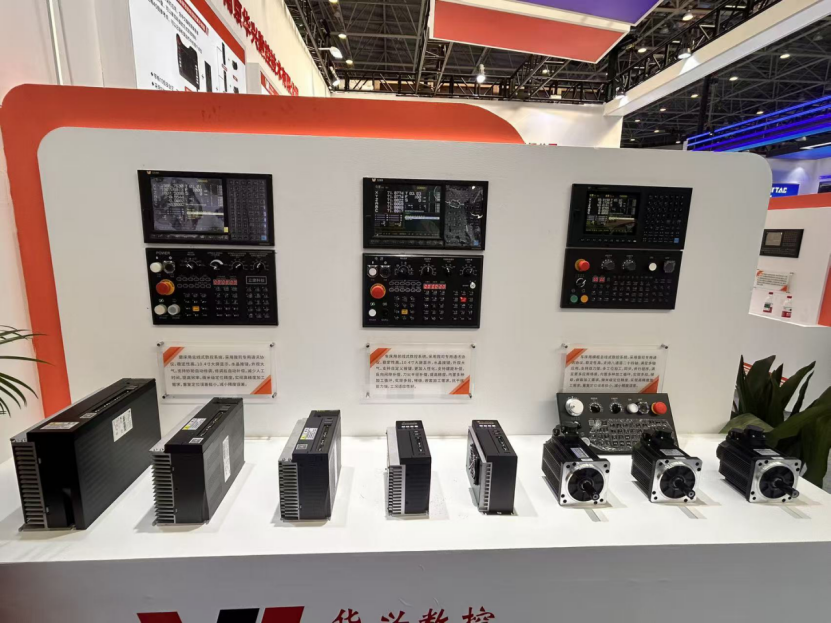

What attracted these buyers to choose Huaxing CNC among numerous suppliers? As one of the mainstream CNC system suppliers in China and a professional manufacturer with a full range of CNC supporting capabilities, Huaxing CNC is committed to providing partners with a complete set of electronic control product solutions for machine tools. At present, Huaxing CNC's product line covers CNC systems, AC servos, spindle servos, AC servo motors, spindle servo motors, and even isolated power transformers. All products are independently designed and produced, combining high cost-effectiveness and high reliability, with an average annual sales of over 50000 sets.

In terms of core technology and production support, Huaxing CNC adopts CPUs with independent intellectual property rights to ensure reliable performance and safe supply of CNC systems. The company has strong hardware facilities, including two SMT surface mount production lines, two high-speed stamping lines for motor stator and rotor, one automatic plug-in production line, servo and spindle stator automatic lines, motor progressive die, fully automatic dipping, painting, baking and drying lines, and complete testing equipment. It produces more than 400000 circuit boards annually and has a strong production capacity of 150000 servo and spindle motors per year. With the commissioning of the second phase of the factory, the company's total factory area has reached 25000 square meters, providing a solid foundation for sustained and stable production.

In this exhibition, Huaxing CNC highlighted the WA-N790XTN/WA-N790XGN 10.4-inch turning milling and grinding CNC system, WA-N750XTN turning milling and grinding CNC system, WA-N780XTN/WA-N785XTN multi axis multi-channel CNC system, GDX bus type multi in one servo drive, HDV series AC asynchronous spindle servo drive, AC asynchronous spindle servo motor, WA-HMI dedicated truss controller, etc. Yuhuan has numerous machine tool enterprises and is an important market for Huaxing CNC products. At present, Huaxing CNC has established service centers in Yuhuan, Ningbo, Cixi and other places to respond to customer needs with "high-quality, fast and convenient" services.

This exhibition fully demonstrated the hard core strength of Huaxing CNC in the field of CNC systems and machine tool matching, and achieved ideal exhibition results. The exhibition has come to an end, and Huaxing CNC's pursuit of service and quality will not come to an end. In the future, Huaxing CNC will continue to be driven by innovation, work together with partners to open a new chapter in intelligent machine tool manufacturing, and continuously inject new momentum into the high-quality development of the industry.