-

E-mail

yanxia.zheng@dne-china.com

-

Phone

13662679502

-

Address

No. 8179 Bao'an Avenue, Bao'an District, Shenzhen

DiNeng Laser (Guangdong) Co., Ltd

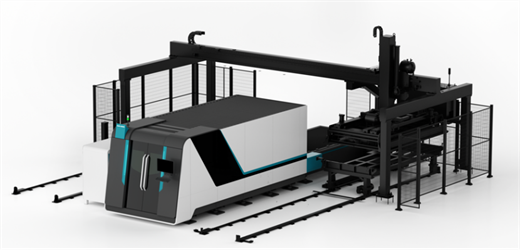

The D-Cell automated production unit of Denon Laser has won the Laser Star Rui Award

Date: 2025-12-01Read: 4

On November 28th, the 4th SRA2025 China Laser Star Rui Summit and Laser Star Rui Award Ceremony were held grandly in Wuhan Optics Valley. The D-Cell laser automation production unit of Denon Laser, with its advanced, efficient, and intelligent core advantages, provides practical and feasible innovative solutions for the high-quality development of the manufacturing industry. It stands out among numerous evaluated products and has successfully won the "Laser Star Rui Award - Best Laser Intelligent Equipment Technology Innovation Award".

This award is jointly organized by the China Laser Star Rui Award Organizing Committee and "Laser Home", and co organized by multiple industry organizations. It is an influential technology certification in the laser field. This award signifies that Denon Laser's research and development strength and technological innovation capability in the field of intelligent manufacturing equipment have once again been highly recognized by the industry.

1、 Technological breakthrough of D-Cell laser automation unit

As an intelligent laser automation unit independently designed and developed by Dinone Laser, D-Cell is deeply integrated with Industry 4.0 technology and has outstanding progressiveness in the industry. Its core advantages are mainly reflected in three dimensions: full process automation, humanized design and flexible adaptability:

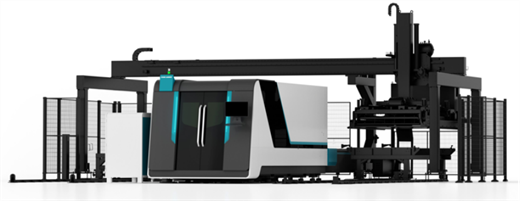

(1) Unmanned entire process, improving efficiency, stabilizing quality, and reducing costs

D-Cell has built a complete automated operation loop from raw material loading to finished product unloading: after the raw materials are transported from the raw material platform to the exchange area, the vacuum suction cup elevator accurately sucks up the raw materials (with fork teeth protection below to prevent slipping) and moves them to the cutting machine workbench; After cutting is completed, the exchange platform automatically replaces raw materials and waste materials, and the elevator takes over the waste and transports it to the waste platform. The entire process requires almost no manual intervention and can achieve continuous "automatic production" with only one person on duty, greatly improving production efficiency, reducing labor costs and production uncertainties, significantly improving production stability and product quality, and becoming an ideal choice for modern intelligent manufacturing.

(2) Humanized design, balancing convenience and safety

In terms of operational experience, D-Cell follows the principle of human-computer interaction, with an intuitive and easy to understand interface and simple operation. Even non professional operators can quickly get started, achieving "foolproof" production management and improving job satisfaction and efficiency; In terms of safety assurance, the system optimizes the loading and unloading process to reduce the physical burden on operators, equipped with advanced protective mechanisms such as safety fences and safety light curtains, strictly adheres to industrial safety standards, and ensures a safe and secure production environment.

(3) Multi technology integration, adapting to diverse needs

D-Cell innovatively integrates advanced technologies such as magnetic slitting, high-precision online thickness measurement, efficient blowing slitting, and mechanical angle adjustment to meet the personalized needs of different customers. It creates a highly flexible and reliable automatic loading and unloading system that can adapt to production needs in different scenarios, demonstrating strong market adaptability.

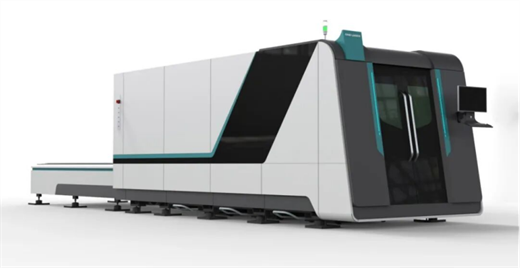

2、 The hardcore strength of the core equipment D-Speed

As the core equipment of D-Cell laser automation unit, the performance parameters of D-Speed high-performance laser cutting machine have reached the industry's advanced level, with the core goals of "efficiency improvement" and "accuracy guarantee", providing solid support for the excellent performance of the overall unit:

Strong power reserve:

The laser power can reach up to 20kW (NonCE/NRTL version, CE/NRTL version up to 12kW), making it easy to cut metal sheets of different thicknesses and materials without frequent equipment adjustments;

Accurate and efficient motion control:

The maximum single axis acceleration is 1.5G, ensuring rapid and precise single axis movement, providing guarantee for fine cutting; The maximum linkage positioning speed is 150m/min, significantly reducing non cutting idle time; The maximum linkage acceleration is 2.0G, which can quickly respond to instructions and maintain efficient rhythm even in complex graphic processing;

Significant improvement in cutting efficiency:

Through self-developed cutting head technology, combined with small core diameter optical fibers, the overall cutting efficiency of 1-3mm boards is directly improved by 22%; Equipped with 7Hz low-pass filtering technology, the efficiency is increased by 15% compared to traditional 5Hz solutions, and the cutting quality is better - the height of the 1-3mm board edge is ≤ 0.02mm, and the roughness of the cutting section is ≤ Ra3.2, achieving a balance between "fast speed" and "high quality".

3、 Adapt to industry trends and expand application boundaries

This honor is the best recognition of our technological innovation path, "said the recipient of the D-Cell Laser Award. The current market size of China's laser equipment has exceeded 150 billion yuan, and intelligence and automation have become the core direction of industry upgrading. D-Cell's research and development precisely responds to the urgent needs of the manufacturing industry in terms of rising labor costs and breakthroughs in efficiency bottlenecks.

At present, D-Cell has been applied in fields such as automotive manufacturing and precision sheet metal, providing key equipment support for customers to build smart factories; It is expected that in the future, the penetration rate in fields such as new energy and aerospace will continue to rise.

4、 Deeply cultivate innovation and assist in the global upgrading of industries

Looking towards the future, Denon Laser will continue to uphold the spirit of craftsmanship, increase research and development investment, rely on profound technological accumulation and lean production processes, and continuously iterate automation and intelligent laser equipment solutions. This award is not only a milestone in the development of the company, but also a new starting point - the company will further expand its application boundaries in the manufacturing field based on the technological breakthroughs of D-Cell units, and contribute to the global upgrading of China's laser industry.