-

E-mail

yanxia.zheng@dne-china.com

-

Phone

13662679502

-

Address

No. 8179 Bao'an Avenue, Bao'an District, Shenzhen

DiNeng Laser (Guangdong) Co., Ltd

New Product Release | D-Speed High Performance Laser Cutting Machine Debuts!

Date: 2025-11-19Read: 4

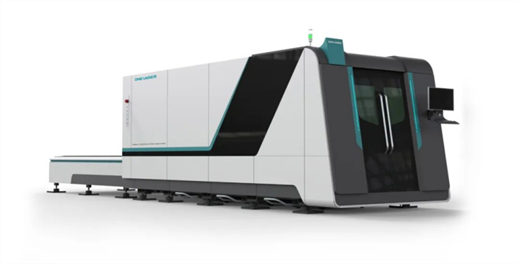

On November 12th, at the opening ceremony of Foshan Intelligent Manufacturing Base, Denon Laser simultaneously released its new flagship equipment - D-Speed high-performance laser cutting machine, becoming the focus of the industry. Regarding the performance of this new product, Dr. You Song, the global CEO of Denon Laser, cleverly analyzed it at the press conference, pointing out the meaning of "Speed":

D-Speed:

S-Swift: Rapid response (referring to the dynamic response performance of equipment);

P - Precision: Precise cutting (referring to the precision control capability of equipment);

E - Efficiency: Efficient output (referring to the comprehensive production efficiency of equipment);

E - Endurable: Stable and durable (referring to the long-term stable operation performance of equipment);

D - Dynamic: Dynamic adaptation.

This equipment is tailor-made for enterprises that pursue cutting efficiency and processing quality. With its core advantages of "high speed, high efficiency, and high precision", as well as intelligent, highly integrated, and automated innovative design, it will help enterprises achieve dual improvement in metal sheet processing efficiency and quality, providing strong momentum for more enterprises to upgrade to "world-class factories".

1、 Core performance:

Fully load parameters, achieve a qualitative leap in efficiency

In the field of metal processing, "efficiency" and "precision" have always been the key for enterprises to break through production capacity bottlenecks. The D-Speed high-performance laser cutting machine precisely anchors this core pain point, focusing on high-precision and high-speed cutting scenarios for various types of metal sheets. Whether it is precision parts as thin as 1mm or high-strength processing of thick plates, it can achieve a dual breakthrough in quality and efficiency, providing strong support for enterprises in the fields of automotive parts, engineering machinery, hardware products, medical equipment, aerospace support, etc.

Luigi, Sales Director of Denon Laser Europe, introduces the D-Speed high-performance laser cutting machine at the new product launch site

As the core of high-performance equipment, D-Speed's performance parameters have reached the industry's advanced level, with each data point towards "efficiency improvement" and "accuracy guarantee":

Strong power reserve: The laser power can reach up to 20kW (NonCE/NRTL version, CE/NRTL version up to 12kW), easily handling metal sheet cutting of different thicknesses and materials, without the need for frequent equipment adjustments;

Accurate and efficient motion control: maximum single axis acceleration of 1.5G, ensuring fast and precise single axis motion, providing guarantee for fine cutting; The maximum linkage positioning speed is 150m/min, significantly reducing non cutting idle time; The maximum linkage acceleration is 2.0G, which can quickly respond to instructions and maintain efficient rhythm even in complex graphic processing;

Significant improvement in cutting efficiency: Through self-developed cutting head technology, combined with small core diameter optical fibers, the overall cutting efficiency of 1-3mm boards is directly increased by 22%; Equipped with 7Hz low-pass filtering technology, the efficiency is increased by 15% compared to traditional 5Hz solutions, and the cutting quality is better - the height of the 1-3mm board edge is ≤ 0.02mm, and the roughness of the cutting section is ≤ Ra3.2, achieving a balance between "fast speed" and "high quality".

2、 Featured features:

From core components to system design, comprehensively reduce costs and increase efficiency

D-Speed deeply fits the production needs of enterprises in detail design, from core components to system configuration, each function serves the purpose of "cost reduction, efficiency improvement, and quality stability":

1. Core components: Dual excellence in durability and performance

Cutting head: The 3/6kW version can be equipped with short focal length and small core diameter optical fibers, and the small light spot brings high energy density, further upgrading the cutting efficiency; Simultaneously considering the universality of consumables and the convenience of maintenance, reducing the cost of consumables and downtime for maintenance in the later stage;

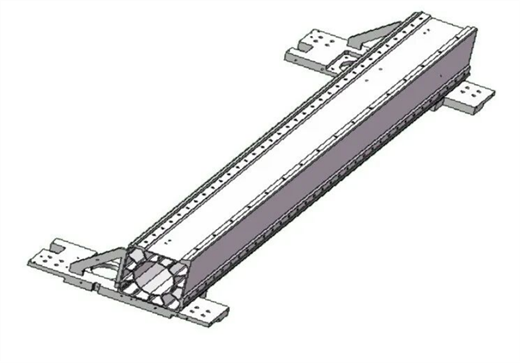

Cutting bridge: made of high-strength aviation aluminum material, formed by precision molds and analyzed for stress, the deformation of the crossbeam is precisely controlled during high-speed and high acceleration dynamic cutting, ensuring stable cutting accuracy;

Z-axis drive system: powered by a high-power Z-axis motor, the speed is increased by 33% and the idle time is significantly reduced; The optimized acceleration performance enhances the overall processing rhythm and provides stable power for complex processes such as flight cutting.

2. Independent electrical cabinet: stable, safe, and easy to maintain

The independent electrical cabinet design is the "safety guard" and "maintenance assistant" of D-Speed: effectively isolating equipment vibration and dust, providing a stable working environment for internal precision electrical components, and reducing failure rates; Centralized layout of electrical modules, diagnosis and maintenance do not need to enter the interior of the host, greatly reducing downtime; At the same time, isolate the high-voltage and high-voltage parts from the operating area to prevent dust and electric shock, ensuring the safety of personnel and equipment.

3. Intelligent options: waste utilization+precise positioning, tapping into production potential

Residual material reproduction function: efficient utilization of cutting waste, reducing raw material waste, simple and efficient operation, saving costs for enterprises;

Visual edge finding function: achieving fast edge finding and ultra-high precision secondary positioning, even if there is a slight deviation in the placement of the board, it can be accurately cut, reducing the rate of operational errors.

3、 Safe and easy to use:

Lowering the threshold to ensure worry free production

D-Speed achieves a balance between safety and operational convenience:

Safety protection: It can be equipped with safety interlock devices to prevent misoperation through mechanical and electrical dual constraints; The anti radiation window complies with CE certification standards, ensuring the health of operators while not affecting processing observation;

Usability design: Customized cutting software development, supporting real-time adjustable process parameters, easy to operate, reducing personnel training costs, and enabling beginners to quickly start production.

4、 Automation solution:

High integration mode, building intelligent production lines

D-Speed provides highly integrated solutions for the automation needs of modern factories

Integrated control: One computer can simultaneously control laser cutting and loading/unloading devices without the need for additional PLC configuration, reducing equipment investment costs;

Standardized configuration: Automation equipment requires no programming and does not need to interface with laser cutting machines, saving debugging time by 70% -90%;

MES central control docking: It can seamlessly integrate with MES central control system to achieve upstream and downstream equipment linkage, easily build fully automated production lines, and help enterprises move towards "intelligent manufacturing".

5、 Packing guarantee:

Worry free logistics and transportation, fast production

D-Speed continues the family design language of Denon Laser, with a stable and atmospheric overall body that combines technological quality with practical attributes. The stable body structure not only provides a solid foundation for high-speed cutting, but also integrates into various modern workshop layouts, conveying the product genes of "reliability and durability" from visual to user experience.

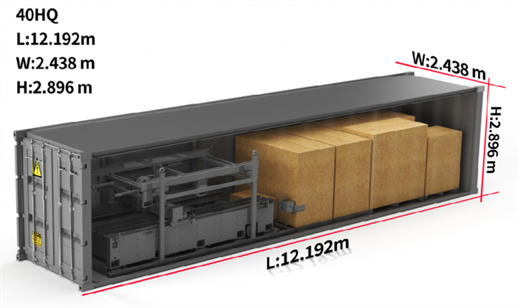

In addition to its exterior design, D-Speed also adopts a professional packaging scheme that balances the safe delivery and rapid production of the equipment: after removing the peripheral sheet metal, the entire machine and its accessories can be loaded into a 40HQ container at once; At the same time, moisture-proof vacuum bags are used for sealed packaging to isolate moisture, salt spray, and oxygen, preventing equipment oxidation and corrosion. Combined with cushioning materials, stable performance is ensured during transportation and storage, and quick commissioning and production can be achieved upon opening the box.

Conclusion

From "improving efficiency" to "ensuring accuracy", from "reducing costs" to "intelligent upgrading", every design of the Denon Laser D-Speed high-performance laser cutting machine is based on a deep understanding of the production needs of the enterprise. As per the mission of Denon Laser - "It is our responsibility and mission to make you a world-class factory", this new product will become a powerful assistant for enterprises to break through production capacity bottlenecks and enhance core competitiveness.