-

E-mail

san.youzhang@163.com

-

Phone

13606747928

-

Address

No. 288 Cizhang Road, Zhangqi Town, Cixi City

Cixi Sanyou Machinery Factory

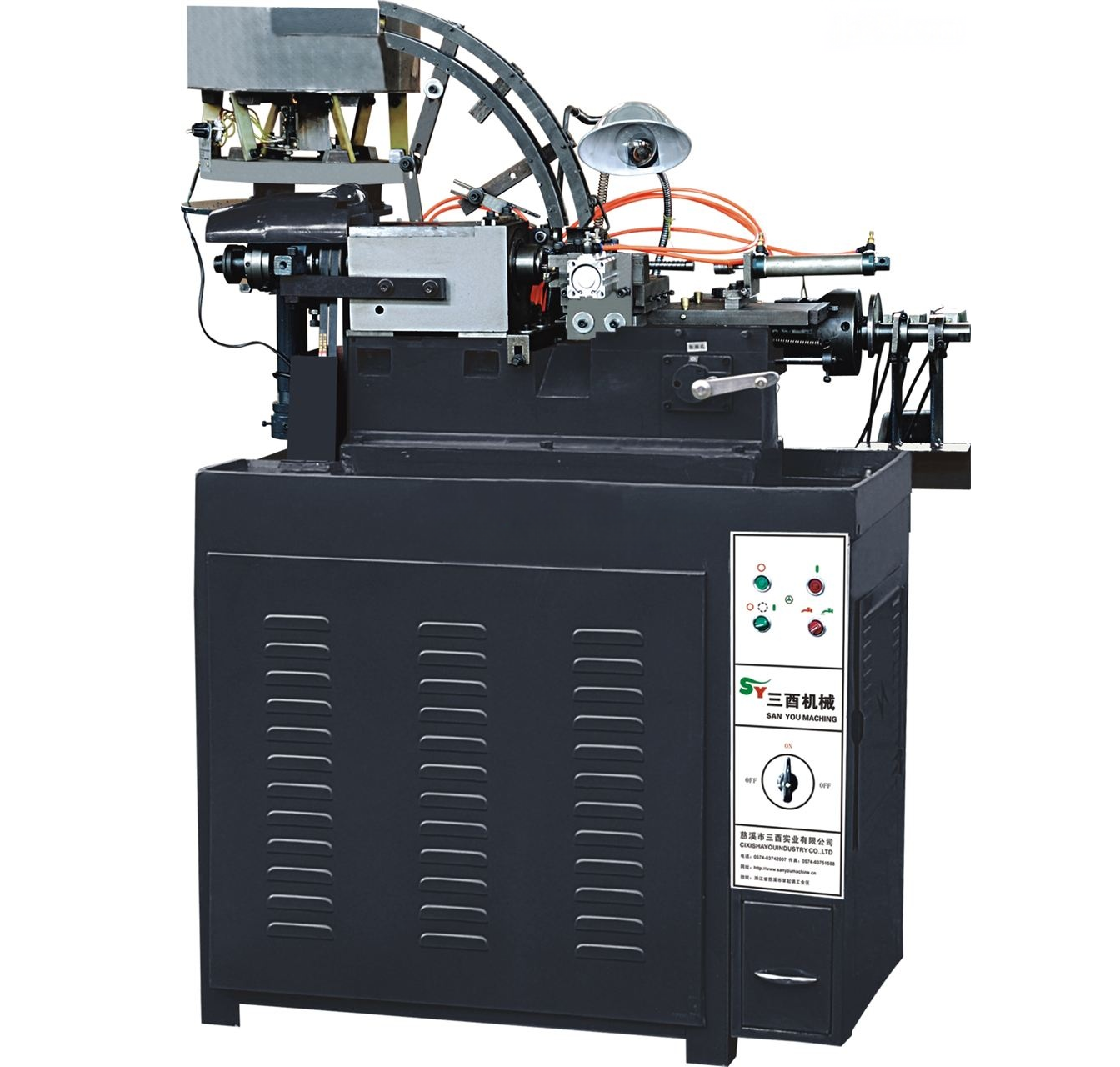

Application of CNC automatic lathe in mold manufacturing

Date: 2025-06-19Read: 6

Mold manufacturing, as a key link in modern industrial production, directly affects the forming effect of products in terms of accuracy and quality. CNC automatic lathes are widely used in the field of mold manufacturing due to their high precision, efficiency, and automation, providing reliable technical support for the processing of complex mold parts.

The high-precision machining capability of CNC automatic lathes is an important guarantee for mold manufacturing. The dimensional accuracy and surface quality requirements of molds are very high, such as the cavity and core of injection molds. The dimensional tolerance usually needs to be controlled within ± 0.01mm, and the surface roughness Ra value is required to be below 0.8 μ m. The CNC automatic lathe can accurately control the motion trajectory of the tool and achieve micrometer level machining accuracy through a closed-loop control system and high-precision servo drive device. At the same time, its high rigidity spindle and precision ball screw pair reduce vibration and errors during the machining process, ensuring the dimensional consistency and surface smoothness of mold parts.

In the processing of complex mold parts, CNC automatic lathes have shown special advantages. Molds often contain various complex structures such as irregular surfaces, deep holes, and threads, which traditional processing equipment cannot meet the requirements. The CNC automatic lathe, with the help of the CNC system, can program and process complex parts. For example, through the multi axis linkage function, die-casting mold inserts with spiral surfaces can be processed; By using an automatic tool changing device, multiple processes such as turning, milling, drilling, and tapping can be completed in one clamping, reducing the number of clamping times for the workpiece, improving processing efficiency, and avoiding positioning errors caused by multiple clamping.

The automated processing characteristics of CNC automatic lathes greatly improve the production efficiency of mold manufacturing. During the mold manufacturing process, mass-produced mold parts require repeated processing. Numerical control automatic lathes can achieve 24-hour continuous automated production by writing machining programs, reducing manual intervention and labor intensity. In addition, the lathe is equipped with an automatic loading and unloading device, which can automatically complete the loading and unloading of workpieces, further improving production efficiency. At the same time, the real-time monitoring and fault diagnosis functions of the CNC system can timely detect abnormal situations during the machining process, avoid the generation of waste products, and ensure the quality and progress of mold manufacturing.

The application of CNC automatic lathes in mold manufacturing not only improves the machining accuracy and production efficiency of molds, but also promotes the development of mold manufacturing technology towards intelligence and automation. With the continuous advancement of CNC technology, CNC automatic lathes will play a more important role in the field of mold manufacturing, providing higher quality mold products for industrial production.