-

E-mail

sales@linkman.com.cn

-

Phone

13511063406

-

Address

No. 3 Longyuan Road, Shilong Economic and Technological Development Zone, Beijing

Beijing Linkman CNC Technology Co., Ltd

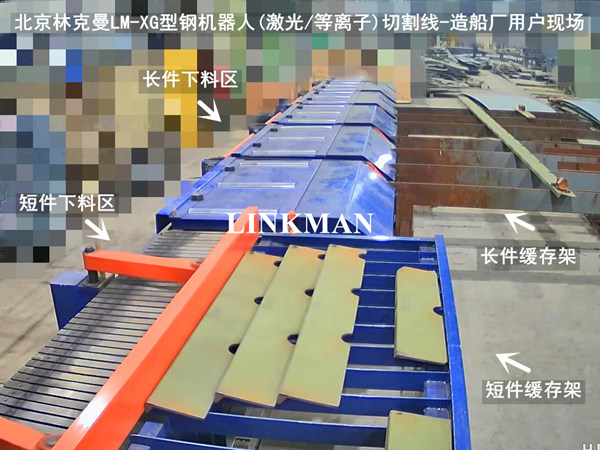

Recently, the LM-XG robot profile automatic cutting line project was completed and delivered to a foreign shipyard. Beijing Linkman products have made contributions in enhancing new quality productivity and improving modern shipbuilding technology and processes. The cutting line consists of a feeding area (feeding buffer rack, feeding conveyor chain, feeding roller conveyor, clamping feeding mechanism, etc.), a cutting area (closed cutting dust removal room/cutting robot/steel locking mechanism/laser deformation measurement and correction mechanism/waste car, etc.), a unloading area (short piece unloading/long piece unloading/short piece buffer rack/long piece buffer rack, etc.), a centralized control console, a dust removal system, offline programming discharge software, machine tool control software, laser/plasma/spray code marking mechanism, etc.

The Beijing Linkman LM-XG robot profile automatic cutting line is suitable for the assembly line cutting of profiles such as spherical flat steel, angle steel, and flat steel with large deformation in industries such as marine engineering and shipbuilding. Through the independent copyright MobotSpace offline programming software and automatic docking with various user shipbuilding design software, its strong price competitiveness and automation level have been well received by domestic and foreign marine engineering and shipbuilding users.

The LM-XG robot profile automatic cutting line can not only significantly improve the production efficiency and workpiece quality of offshore shipyards, but also further reduce workshop production personnel and management costs, providing accurate workpiece dimensions and clean welding grooves for large-scale components in industries such as offshore and shipbuilding.

The LM-XG robot profile automatic cutting line is arranged in three working areas: loading, cutting, and unloading. It can automatically interface with user shipbuilding design software such as AM (Tribon) and SPD to achieve automatic programming optimization of profile (ball flat steel, angle steel) workpieces, data statistics, coding and marking, and automatic cutting.

LM-XG has the characteristics of high automation, low maintenance cost, small equipment footprint, and convenient relocation and transportation. It adopts a flexible steel clamping mechanism combined with roller conveyor to transport workpieces. The product has added a steel fixed pressure roller mechanism device and a steel deformation laser measurement and correction device in the cutting room.

MobotSpace, an offline programming and nesting software copyrighted by Beijing Linkman, can automatically extract thousands of profile workpiece information from shipbuilding design software such as AM (Tribon) and SPD within seconds, eliminating the traditional tedious manual programming and nesting requirements. It can meet the programming and nesting requirements of 24-hour production lines in the marine shipbuilding industry, reducing errors caused by manual programming and nesting.

MobotSpace can be set up in design or process departments to easily complete offline programming and automatic nesting of cutting robots, as well as coding, marking, and cutting simulation in the office. It automatically generates cutting robot program code, which can be downloaded directly to the workshop cutting robot through USB or network, reducing the labor intensity of operators and greatly improving processing efficiency and cutting accuracy.

The following figure shows the user site and partial performance of LM-XG Offshore Shipyard:

For more information, please follow Beijing Linkman WeChat official account