-

E-mail

info@khkchilun.com

-

Phone

15713836720

-

Address

1508, Building B, Erqi Center, No. 106 Hanghai Middle Road, Zhengzhou City

Zhengzhou Representative Office of Japan Kohara Gear Industry Co., Ltd

spur gear

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

SSAY1-45spur gearIntroduction:

KHK Gear Industry can produce a variety of products based on various conditions such as different modules, tooth numbers, precision, shapes, materials, as well as the presence or absence of heat treatment and grindingspur gearThe spur gear in the KHK product sample is commonly referred to asspur gear.

What isspur gear?

spur gearSpur gears, also known as spur gears, are cylindrical gears (mechanical elements) installed on two parallel shafts, with one shaft driving the other shaft to rotate.spur gearIt has the advantages of easy production and high precision. Gears can be divided into three types based on the relative position of the gear shaft: parallel axis gears, cross axis gears, and cross axis gears.spur gearLike helical gears and racks, it belongs to parallel axis gears.spur gearThe meshing of spur gears is almost a rolling contact, and its power transmission efficiency is 95-98%, which is very high. A pair of meshingspur gearMedium, large ones are called large gears, and small ones are called small gears.

spur gearThe material

KHK standardspur gearUse carbon steel S45C, SCM440 (medium carbon alloy steel), and SCM415 (low carbon alloy steel) specifically designed for mechanical structures according to JIS specifications, gray iron FC200 in cast iron, SUS303 and SUS304 in stainless steel, C3604 (quick cut copper) for non-ferrous metals, MC901 and MC602ST for engineering plastics, and other materials. Of course, different countries and gear manufacturers use different specifications. For example, DIN in Germany, AISI, SAE, ASTM, AGMA in the United States, etc. For materials, we can perform heat treatments such as high-frequency quenching and carburizing quenching to increase hardness, as well as surface treatments to improve wear resistance and rust prevention.

Aboutspur gearThe shape and size of the teeth

The gear teeth used in industrial machinery are generally involute teeth. In addition, the size of teeth is generally represented by modulus, and the larger the modulus value, the larger the teeth. By increasing the gear module, a stronger allowable torque can be obtained.

KHK standardspur gearThe selection

Customers are selecting from the KHK standard gear product linespur gearWhen selecting, you can pay attention to the following selection points.

·The required speed communication ratio

·Load torque of gears

This element is affected by the modulus size and quenching

·The operating environment of gears

For example, gears are used in environments that are prone to rusting

·Required smoothness and noise level

Is this element affected by gear accuracy and grinding

·Gear shape

Do you need wheels, how long are the wheels, or do they come with axles

Xiaoyuan Gear Car Industrial Co., Ltd. provides a variety of products based on customer usage purposesspur gearPlease refer to for detailsspur gearProduct line.

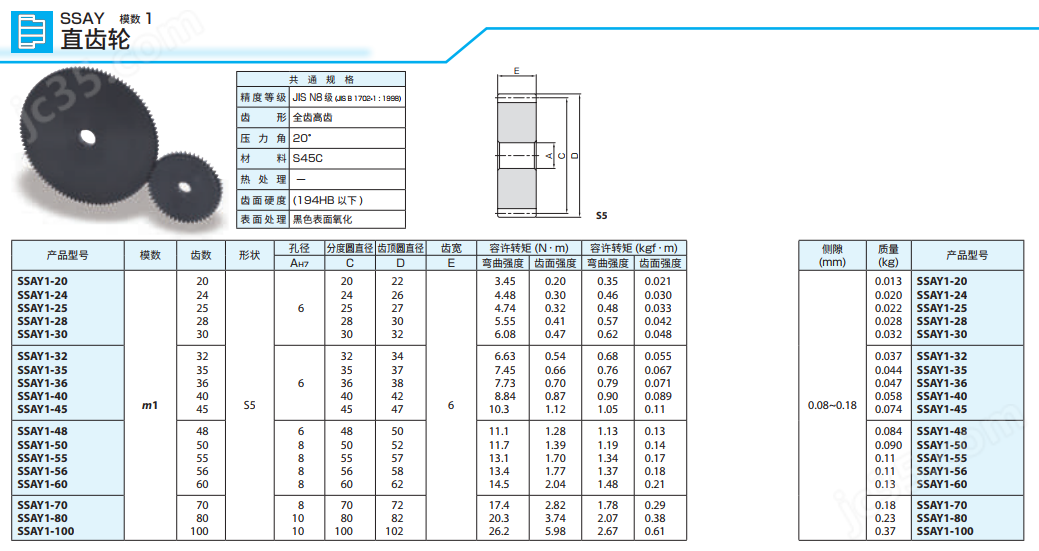

Modulus: 1

Material: S45C

Heat treatment: 1

Tooth surface machining: cutting

Gear accuracy: JIS N8 Note 3

A gear with narrow tooth width. Suitable for light load applications.

SSAY1-45spur gearSpecifications and parameters: