-

E-mail

zopo2023@zopocnc.com

-

Phone

19155985069

-

Address

No. 19-3001, HSBC Plaza, No. 269, Mount Huangshan Road, Huizhou District, Mount Huangshan City, Anhui Province

Anhui Zhuopu Intelligent Equipment Co., Ltd

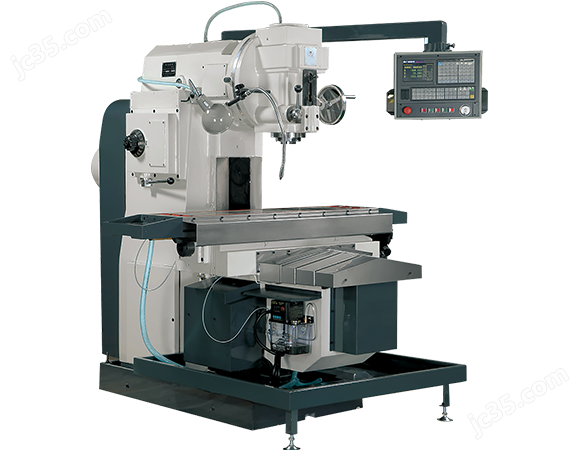

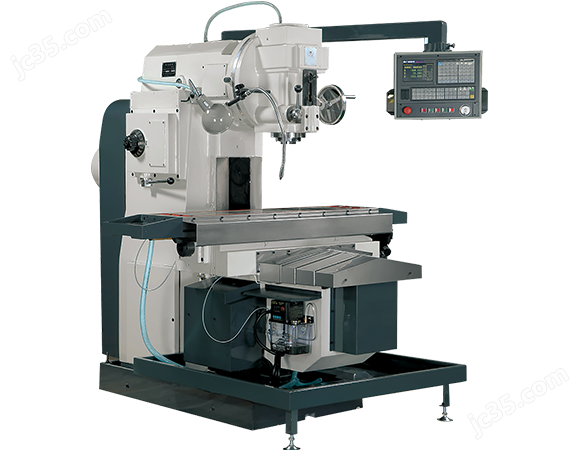

XK5030B CNC lifting table milling machine

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

XK5030B

CNC lifting table milling machine

580/260/90mm

Three-axis stroke

300×1100mm

Workbench area

2500rpm

maximum speed

3000/3000/1500mm/min

rapid traverse speed

Structural rigidity+precise stability

High rigidity and stability mechanical structure

Wide range of processing applications

Processing range

unit

Three-axis stroke

580/260/90 mm

Maximum axial movement distance of the spindle

90mm

Distance from spindle end face to worktable

70-430 mm

The distance from the vertical guide rail of the bed to the centerline of the spindle

290 mm

Distance from the vertical guide rail of the bed to the center of the worktable

160-420 mm

workbench

unit

Workbench area

300x1100mm

T-slot

3-14*63mm

The maximum load-bearing capacity of the workbench

280kg

spindle

unit

Spindle hole taper

7:24 No.40

spindle power

4KW

maximum speed

2500rpm

feed

unit

Maximum feed rate

2000mm/min

Fast moving speed

3000/3000/1500mm/min

precision

unit

定位精度

0.025mm

Repetitive positioning accuracy

0.015mm

Overall dimensions

unit

Machine dimensions

1500*1470*1800mm

Machine weight (approximately)

1800kg