-

E-mail

li.peng7322@163.com

-

Phone

13880213354

-

Address

No. 79 Tianqin West Street, High tech Zone (West District), Chengdu City

- PM dynamic beam gantry machining center

- additive manufacturing

- PH horizontal machining center

- PHU series five axis horizontal machining center

- PHD horizontal five axis machining center

- PD series five axis machining center

- PE series five axis vertical machining center

- PB series elevated gantry machining center

- PL series rail type vertical machining center

Chengdu Yuding Special Processing Technology Co., Ltd

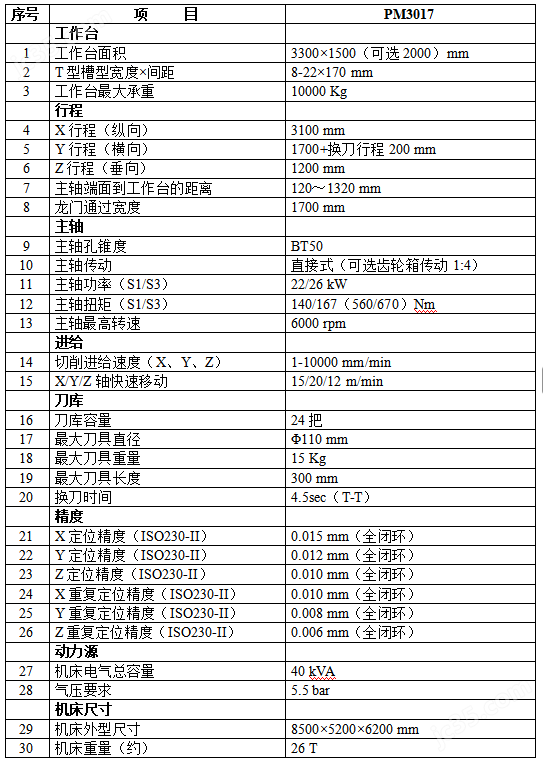

PM dynamic beam gantry machining center

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

PMDynamic beam gantry machining centerChengdu Yuding Special Processing Technology Co., Ltd. has fully digested and absorbed the characteristics of similar foreign products, and developed electromechanical integrated CNC products using modern manufacturing technology to meet the needs of complex spatial surface processing and automation processing characteristics, with good performance price ratio.

PMDynamic beam gantry machining centerAdopting mainstream technology, it is a workbench, crossbeam, and spindle box High precision and high rigidity gantry machining center for skateboard movement. The machine tool adopts a fixed column and moving beam structure, with a bed and double column fixed and immovable structure layout. The movement of the crossbeam is avoided due to different heights of the workpieceZInsufficient shaft rigidity affects the machining accuracy of parts, especially suitable for processing titanium alloys and high-strength steels.The machine tool can achieve the function of a five axis gantry machining center through five axis five linkage. The specific layout is: the worktable is located in the front and back of the bed(XThe double swing milling head spindle box is fixed on the sliding plate and moved left and right along the crossbeam(YMove upwards and downwards with the crossbeam on the double columns(ZMovement towards), dual swing milling head implementationAAxis swing andCAxis rotation. After a single clamping of the parts, it can achieve five sided machining, completing milling, boring, drilling, tapping and other processes for medium and large complex parts. It has a high degree of automation and high machining accuracy, and is suitable for semi precision machining and precision machining of large and medium-sized complex parts in industries such as military, aerospace, petroleum machinery, molds, automobiles, railways, ships, etc.

During the production and manufacturing process of machine tools, strict adherence toISO9001:2015The quality control shall be carried out in accordance with the provisions of the Quality Management System standard, and the testing and experimental methods of relevant national and international standards shall be implemented. Among them, the main technical indicators such as geometric accuracy and positioning accuracy, spindle temperature rise, overall noise, rapid response characteristics, and low-speed feed performance that are actually achieved shall be equal to or higher than the values specified in the national and international standards0~20%These contents constitute the high-quality image of the product from the inside to the outside.

Standard Configuration

SIEMENS 840DCNC system, fully closed-loop feed axisA/CFully enclosed shaft, continuous cooling, automatic chip conveyor, cam tool magazine, processing lighting, three color warning light, cutting blowing system, cutting fluid system for processing, automatic lubrication system, hand cranked pulse generator, manual blowing, fully enclosed protective cover, horizontal adjustment bolt and shim.

Option function

FANUC 0i MF plus/30i/31i/32i MBTheSIEMENS 828D、Tool probe, workpiece probe, electrical cabinet air conditioner, voltage regulator power supply, manual water gun, oil mist collector, spindle high-power/high torque.