-

E-mail

david.du2006@163.com

-

Phone

18551290099

-

Address

Room 602, 6th Floor, Building 1, No. 98 Jujin Road, Taiping Street, Xiangcheng District, Suzhou City, Jiangsu Province

Product Categories

Suzhou Jundao CNC Machinery Co., Ltd

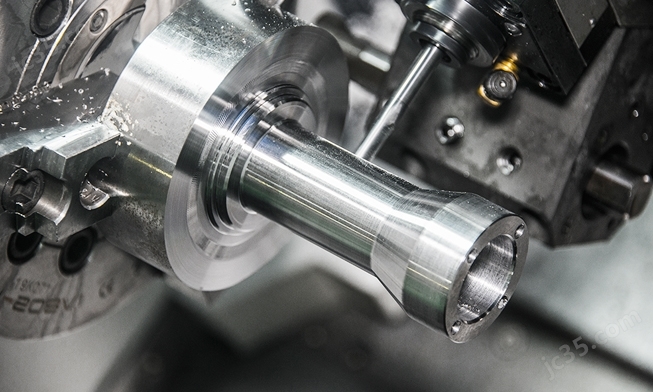

Modern Weiya turning and milling composite CNC lathe

NegotiableUpdate on 02/12

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

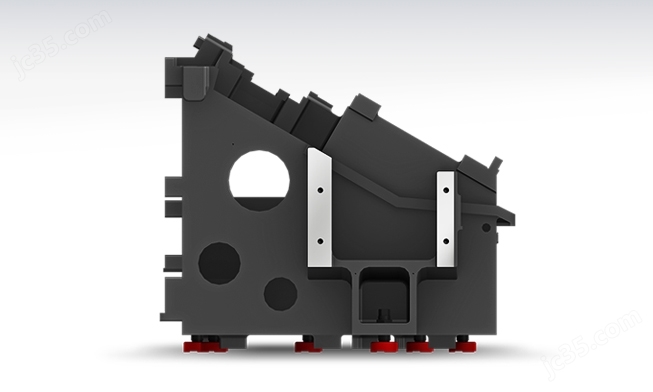

● Achieve high-quality composite machining $r $n through a compensating Y-axis system ● Strengthen the processing of extra long blanks by constructing an extended bed product line to address $r $n ● Adopt 30&# 176; Tilted high rigidity integrated bed body $r $n ● Designed with wire rails to achieve high-speed/high-quality machining performance $r $n ● Equipped with a convenient NC hydraulic tailstock (SE2600Y) $r $n ● Synchronized control of spindle and sub spindle to achieve process integration (SE2608SY) $r $n ● Equipped with FANUC 0i PLUS (10.4 "touch screen)

Product Details

SE2608Y | SE2608SY

Product Introduction

Specifications

| Description | Unit | SE2608Y | SE2608SY |

| ZuiLarge workpiece diameter | mm | 380 | 380 |

| ZuiLength of large workpiece | mm | 621 | 621 |

| chuck size | inch | 10″ | Main 10' |

| Sub 6' | |||

| Spindle drive mode | - | Belt | Belt |

| speed | r/min | 3,500 | 3,500 |

| Main spindle output | kW | 18.5/15 | 18.5/15 |

| Spindle torque | N.m | 300.2/182.6 | 300.2/182.6 |

| ZuiLarge transfer distance (X/Y/Z/ZB) | mm | 255/110/680/- | 255/110/680/660 |

| Fast feed rate (X/Y/Z/ZB) | m/min | 30/10/30/- | 30/10/30/15 |

| guide rail type | - | LM | LM |

| number of tools | EA | 12 | 12 |

| Tool size | mm | 25/40 | 25/40 |

| ZuiHigh rotational speed | r/min | 6,000 | 6,000 |

The device configuration marked on this webpage is standard configuration, and in order to improve quality, there may be situations where changes are made without prior notice

If you need additional information such as option configuration, please refer to the attached sample materials