-

E-mail

15689545718@163.com

-

Phone

15689545718

-

Address

No. 2 Fuyuan Road, Beicheng Entrepreneurship Park, Qingyun Economic Development Zone, Dezhou City, Shandong Province

Dezhou Haichuang Intelligent Equipment Co., Ltd

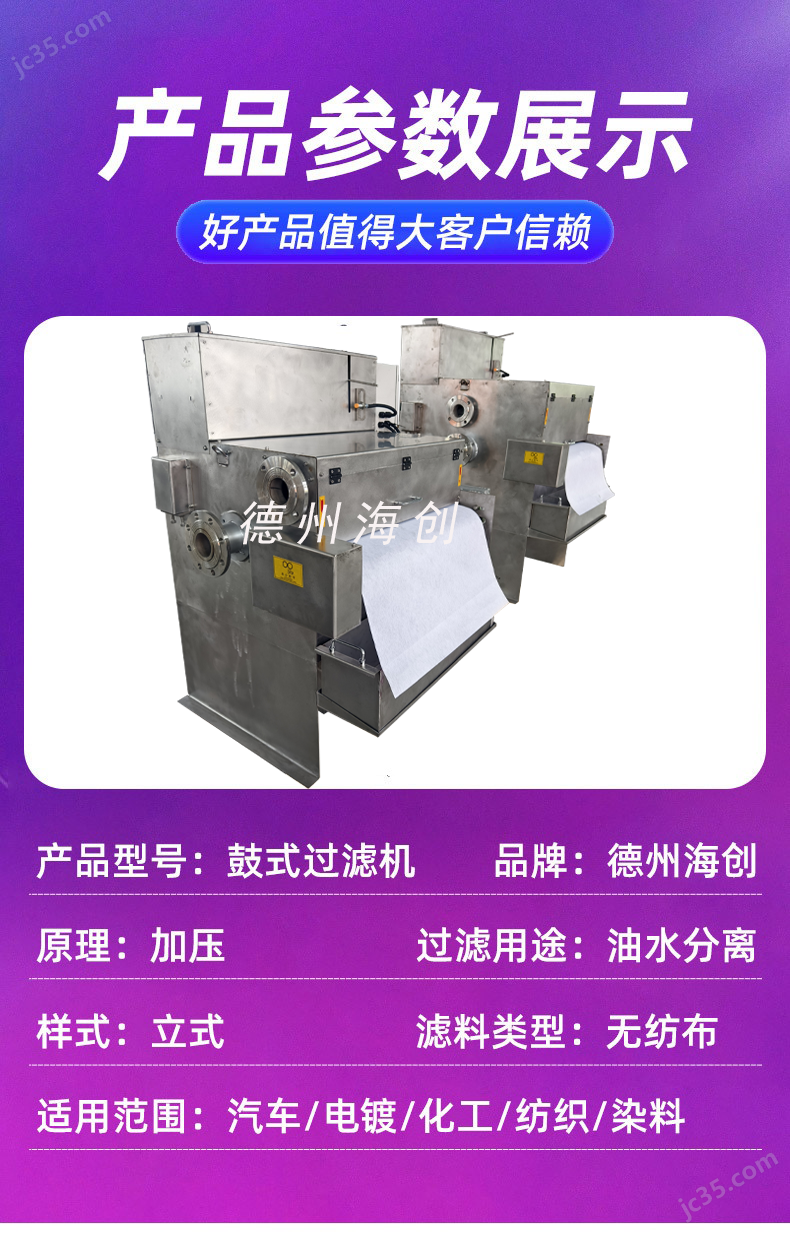

Manufacturer supplied precision stainless steel drum paper tape filter machine

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Drum paper tape filter machineIt is a common filtering device. The following is a detailed introduction to the manufacturer's direct supply precision stainless steel drum paper tape filter:

structural composition

Liquid tank: used to store the liquid to be filtered, providing space and liquid level support for the filtration process.

Waste cloth box: Collect paper tape and impurities contaminated during the filtration process for centralized processing.

Filtering non-woven fabric (paper tape): It is a key component for achieving filtering function, usually composed of multiple layers of non-woven fabric or filter paper, with a certain pore size and filtering accuracy, capable of intercepting impurities in liquids.

Transmission structure: including chains, wire mesh, etc., in a circular arc state. The non-woven fabric laid on top also has a circular arc state, deepening the depth of the liquid pool and improving the utilization rate of the filter cloth.

Drum plate: It is one of the core components of the filter machine, usually composed of two connected rollers. The two roller chains connected by the filter paper support net ride on the two chain edges of the drum. When the drive chain on the power shaft runs, it drives the drum to rotate, and the filter paper pressed between the chain and the drum also moves, thus achieving the function of outputting filter paper.

Message agency: When the liquid level of the sewage rises to the specified height, the liquid level controller sends a message, starts the reducer, and realizes the automatic replacement of the filter cloth.

Reducer: Based on the signal from the transmission mechanism, control the operating speed of the transmission structure, drag the filter cloth, and make the dirt and dirty cloth fall into the collection box.

Liquid pump: delivers filtered pure liquid to the host or other designated location.

working principle

The contaminated liquid carrying impurities flows onto the non-woven fabric through a water flow buffer device, and the impurities are isolated by the filter cloth to form a filter layer. As the filtration process progresses, the filter layer becomes thicker and the liquid level of the contaminated liquid rises.

When the liquid level rises to the specified height, the floating liquid level controller sends a signal, the reducer starts, and the filter cloth is dragged. The dirt and dirty cloth fall into the collection tank, thus achieving automatic replacement of the filter cloth.

After the filter cloth is updated, the liquid level of the dirty liquid drops, the reducer stops rotating, and the machine enters the next filtering cycle. The filtered pure liquid is transported to the host by the liquid pump.

Product Features

High filtration accuracy: It can effectively remove small particles and impurities, ensuring the cleanliness of cutting fluid. The filtration accuracy is generally between 15-20 μ m.

Large filtration area: Due to the larger surface area of drum paper tape, it can accommodate more impurities, thereby extending the service life of the filter machine.

High degree of automation: Usually equipped with automatic control systems, it can achieve functions such as automatic filtration, cleaning, and unloading, improve production efficiency, and reduce manual operations.

Small footprint: With a compact structure and small space occupation, it is suitable for installation in places with limited space, such as near machine tools or corners of workshops.

Large pool depth: Compared to flat mesh paper tape filters, drum paper tape filters have a larger pool depth, higher utilization of filter cloth, and lower operating costs.

Scope of Application

Metal processing industry: widely used for filtering coolant in metal grinding, cutting and other processes, such as iron, copper, aluminum, nickel and other metals processing. It can effectively remove impurities such as metal chips and grinding chips in the cutting fluid, ensuring the stability and quality of the processing process.

Mao embryo parts cleaning system: It can be used for filtering the cleaning solution of the Mao embryo parts cleaning system, removing impurities such as oil stains, dust, and iron filings on the surface of the parts, and improving the cleaning effect.

Other fields: Manufacturer supplied precision stainless steel drum paper tape filters are also suitable for removing impurities from industrial water, organic solutions, and other solutions, such as in the chemical, electronic, pharmaceutical, and other industries, for filtering liquids containing impurities.