-

E-mail

qddetianrun@163.com

-

Phone

18116296609

-

Address

1605, Building A, Liancheng International, No. 758 Jingqi Road, Huaiyin District, Jinan City, Shandong Province

Qingdao Detianrun Electromechanical Technology Co., Ltd

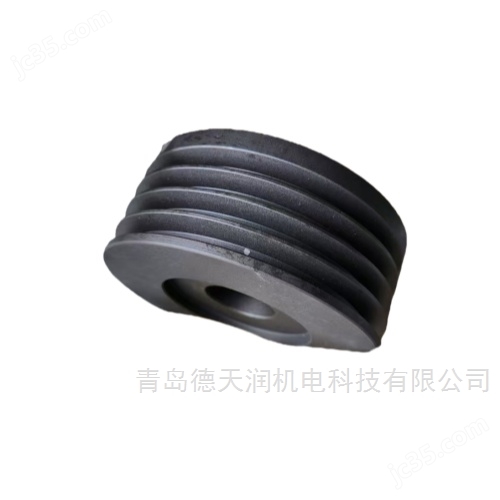

Main Xinde CNC external grinding belt pulley

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Main Xinde CNC external grinding belt pulleyApplicable to

Main Xinde CNC cylindrical grinder (cut in type) GP-CNC series: G32P/G38P/G45P-50/60/75/100/150/200CNC

Main Xinde CNC cylindrical grinder (cut in type) G18P/20P/25P-40CNC series: G18P-40CNC G20P-40CNC G25P-50CNC

Main Xinde CNC cylindrical grinder (angle type) GA-CNC series: G32A/G38A/G45A-35/50/80/120CNC

Main Xinde CNC cylindrical grinder (angle type) G25A-35CNC series: G20A-30CNC G25A-35CNC, etc.

Main Xinde CNC external grinding belt pulley

Power transmission:By coordinating the belt and pulley, the power of the motor is efficiently transmitted to the grinding wheel spindle or inner grinding tool spindle, ensuring that the grinding wheel obtains the required speed and torque.

Improve transmission accuracy and stability:The application of keyless synchronous pulleys can achieve non sliding and backlash free transmission, reduce installation errors, improve spindle rotation accuracy and feed system motion stability, thereby ensuring workpiece processing quality.

Vibration and noise reduction:Optimizing the tightness of the belt can significantly reduce machine tool vibration, while the pulley system can absorb impact and reduce noise propagation.

Security control:In the design of grinding machines with shared motors, the pulley transmission needs to be coordinated with safe operations (such as disassembling the outer grinding belt to avoid conflicts during inner grinding) to prevent accidental operation.

Load bearing and unloading:The use of unloading belt pulley scheme (such as multi wedge belt pulley installed on the bracket instead of the main shaft) can reduce the radial force borne by the main shaft, reduce the risk of deformation, and improve the bearing capacity and service life of the main shaft.