-

E-mail

runfine.filter@163.com

-

Phone

13515452159

-

Address

Zhifu District, Yantai City

- Copper wire drawing filter, non-woven filter paper for water tank

- Flat bed filtration system with matching filter paper

- magnetic coolant separator

- Paper tape filtering system

- Specialized machine tool filter water tank

- Paper tape filter

- Drum type paper tape quenching liquid filtration device

- Skimmer belt

- Magnetic filter machine

- Online filtering device for machine tool coolant

Yantai Yunfan Filtration System Co., Ltd

Machine tool emulsion cooling filtration and oil removal device

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Machine tool emulsion cooling filtration and oil removal device

Technical Parameters of Skinner lotion Cooling and Filtering Device

Water tank capacity: 8 m³

Operating Temperature: 25 – 28°C

Content of suspended steel particles in lotion: 50 kg/h

filtration accuracy: 20 - 25 μm

Cooling water consumption of peeling machine: 200 l/min,4 bar

Lotion concentration: 4 - 5%

External cooling devices, such as heat exchangers used on production line cooling water or refrigeration units.

The device includes a pump and a pipeline for supplying emulsion to the peeling machine.

Filtering device:

The heavy particle sediment in the water tank is transported to the slag collection box by a scraper conveyor

Magnetic pre filter

Filter paper type filtration device, including pump

Other optional devices

Lotion mixing and batching device

Floating oil absorption machine

External cooling system device

Electrical controller

Emulsion filtration device for work roll grinder

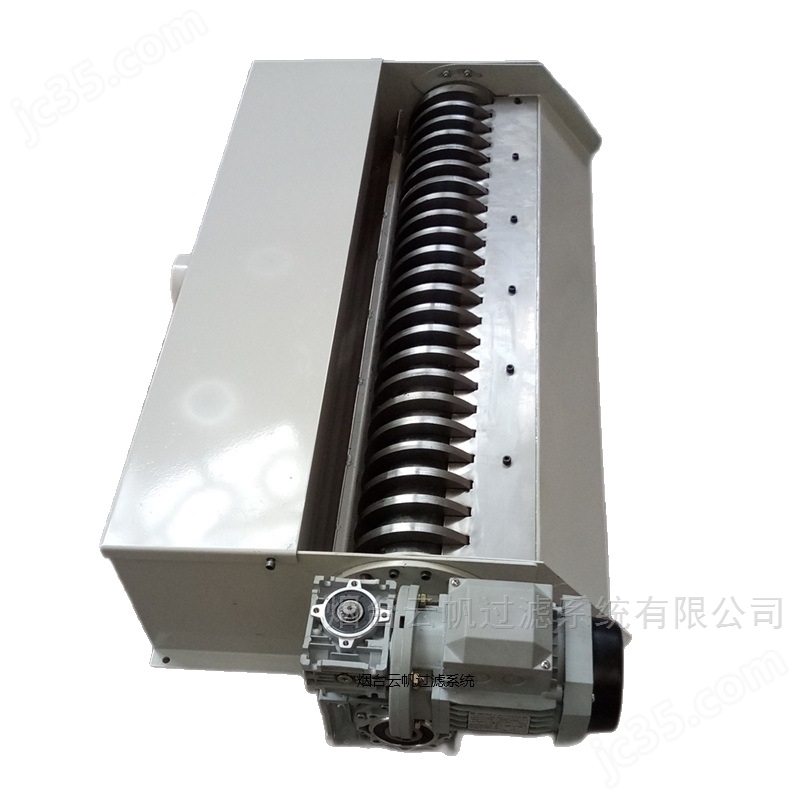

One set of emulsion filtration device, including frame, plate mesh belt reduction transmission part, magnetic roller transmission part, and electronic control part.

Main parameters of magnetic separation system:

Filtering ability:>300L/min

Filter area:>2.9m2

Dimensions (length x width):3000mm×1300mm

Slag removal rate:95%

Technical requirements for magnetic separation filtration system:

Strong separation effect, clean slag discharge, filtration accuracy ≤20M.

Good durability, the conveyor belt mesh needs to be made of stainless steel material, which is sturdy, durable, non deformable, and has strong tensile strength. Under normal maintenance, it can operate continuously for one year without maintenance.

Easy to operate, with automatic and manual control of the mesh belt, adjustable intermittent and operating time.

Working principle of magnetic separation system:

The polluted coolant discharged from the grinder first passes through the magnetic partition of the magnetic separation system to separate and discharge the iron filings. Then, it is transported to the filtering area through a plate mesh filter paper belt to separate and filter the residual iron filings and grinding wheel mud in the coolant, so as to fully purify the coolant.

Machine tool emulsion cooling filtration and oil removal deviceCustomizable