-

E-mail

zopo2023@zopocnc.com

-

Phone

19155985069

-

Address

No. 19-3001, HSBC Plaza, No. 269, Mount Huangshan Road, Huizhou District, Mount Huangshan City, Anhui Province

Anhui Zhuopu Intelligent Equipment Co., Ltd

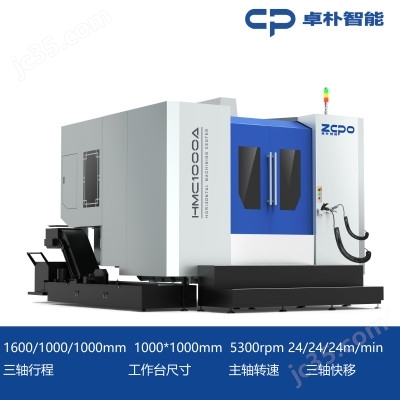

Horizontal machining center inverted T-shaped structure single worktable

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

HMC1000A

Inverted T-shaped structure workbench

Optimal selection for large-scale automated product line processing

1600/1000/1000mm

Three-axis stroke

1000x1000mm

Workbench area

5300rpm

maximum speed

20/20/20m/min

rapid traverse speed

Inverted T-shaped bed

High precision double nut ball screw

Ultra high rigidity, high precision

Application Industry

Processing range

unit

Three-axis stroke

1600/1000/1000mm

Distance from spindle centerline to worktable

0-1000mm

Distance from the center of the workbench to the end face of the spindle

300-1300mm

workbench

unit

Workbench area

1000*1000mm

台面形式

7-22*125mm

Workpiece rotation diameter

Φ1700

The maximum load-bearing capacity of the workbench

1800kg

spindle

unit

Spindle hole taper

BT50

spindle power

15/18.5KW

maximum speed

5300 (belt) rpm

feed

unit

Maximum feed rate

6000mm/min

Fast moving speed

24/24/24m/min

tool magazine

unit

Tool magazine capacity

24T

tool change time

5.5S

precision

unit

定位精度

0.012mm

Repetitive positioning accuracy

0.008mm

B-axis indexing accuracy

10''

B-axis repeated indexing accuracy

2''

Overall dimensions

unit

Machine dimensions

6000*4500*3350mm

Machine weight (approximately)

18000kg