-

E-mail

18936952975@163.com

-

Phone

19352696688

-

Address

No. 9 Kechuang Road, Sucheng Economic Development Zone, Suqian City

Jonuc CNC Equipment (Jiangsu) Co., Ltd

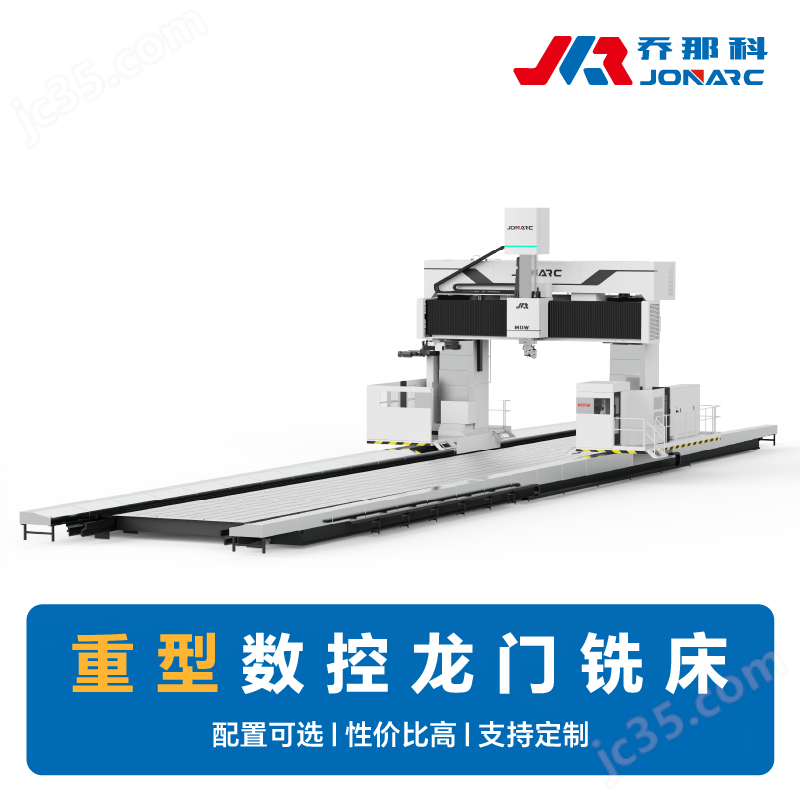

Heavy duty CNC gantry boring and milling machine

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

| Heavy duty CNC gantry boring and milling machine |

Longmen width: optional 3.5, 4.2, 4.3, 4.8, 5.2, 5.8, 6.2, 6.8 meters

Workbench length: optional 4, 5, 6, 10, 12, 16 meters

The above parameter configurations are all standard models, and can also be freely customized according to customer needs

More heavy-duty CNC gantry milling machine models, technical parameters, and configuration plans;

Please clickHeavy duty CNC gantry milling machineList page to learn more about this series of models;

If you would like to view other CNC gantry milling machine models such as fixed beam type, dynamic column type, dynamic beam type, and elevated bridge type;

Please clickCNC gantry milling machineEquipment classification page, where you can browse all models for more efficient selection!

Heavy duty CNC gantry boring and milling machineseries Product Advantage Introduction

1、 Longmen frame, high load-bearing structure design

The heavy-duty CNC gantry milling machine adopts a gantry frame structure and a wide span column layout. The overall center of gravity of the machine is low, the support is strong, and it has excellent seismic and torsional resistance.

The main structure adopts high-strength integrated casting, which is treated with two tempering and vibration aging processes to effectively eliminate internal stress.

2、 High rigidity structure, stability achieves cutting force

The whole machine undergoes FEM finite element structural analysis to optimize and strengthen the design of the bed, crossbeam, column, and sliding saddle, ensuring a short force path and small deformation during cutting.

The dual column integrated gantry frame effectively suppresses vibration and torque offset, ensuring that the machine tool maintains smoothness and precision during high torque cutting.

3、 Flexible configuration to meet different processing needs

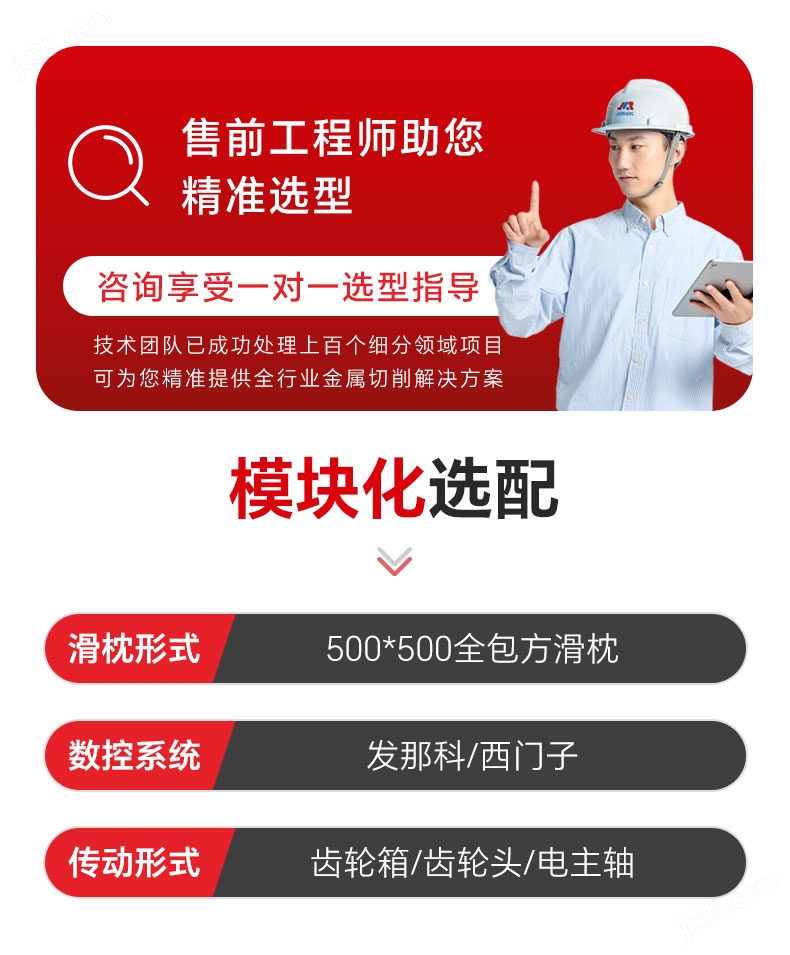

Numerical Control System:Optional mainstream brands such as Fanuc and Siemens;

Spindle configuration:Optional direct connection, gearbox, gear head, and electric spindle structure;

Knife library expansion:It can carry 24-60 chain or disc type tool magazines, support automatic tool changing and tool life management system, ensuring stable and reliable continuous machining.

Guide screw:Optional THK or INA brand heavy-duty roller track and large-diameter ball screw, with strong load-bearing capacity and high transmission efficiency;

Functional attachments:Expandable right angle milling head, universal milling head, extended milling head, automatic head changing system, etc., to achieve complex surface and five sided machining.

4、 Full process quality control, stable accuracy as before

Jonuc adheres to the concept of full process quality control, ensuring that every heavy-duty machine tool can withstand industrial limit verification before leaving the factory.

Design phase:Based on finite element stress simulation and thermal equilibrium simulation, the deformation trend is corrected in advance;

Processing process:The core parts are processed by high-precision machine tools such as Japanese Okuma, SNK and Taiwan, China Doosan;

Assembly process:Implement standardized management of precision assembly, and perform torque control and positioning detection on key nodes;

Testing process:The entire machine is tested using laser interferometers, ball bar instruments, three coordinate systems, dynamic balancing, and long-term load cutting to ensure "high precision upon delivery and stability upon production".

5、 Strong processing capability, capable of handling complex working conditions

The equipment can perform multi process machining such as milling, drilling, boring, reaming, tapping, and hole expansion, and supports accessory milling heads to achieve five sided machining and multi angle composite machining.

6、 Complete manufacturing system and comprehensive service guarantee

The company has more than 20 after-sales service outlets nationwide, providing full lifecycle support such as remote diagnosis, precision calibration, function expansion, and preventive maintenance.