-

E-mail

liuhaijunsh@yeah.net

-

Phone

13661760867

-

Address

101, Building 2, No. 55 Jingbian 1st Road, Balidian Town, Wuxing District, Huzhou City, Zhejiang Province

Product Categories

Nazai Intelligent Technology (Zhejiang) Co., Ltd

Four axis four linkage CNC tool grinder

NegotiableUpdate on 01/08

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

The NZ-04S four axis four linkage CNC tool grinder adopts fully imported servo motors and screw guides for all axes, with high precision and resolution, ensuring the high production quality and efficiency of the machine tool; The process of multi station grinding and multi wheel group grinding, which has been practical for many years, can ensure the quality of tool production and greatly improve the efficiency of tool production.

Product Details

NZ-04S Four Axis Four Linkage CNC Tool Grinding Machine

1、 Product features:

1. Focused on production: standard milling cutters, aluminum processing cutters, acrylic milling cutters, chamfering cutters, tap slotting.

2. The machine tool adopts the process of multi station grinding and multi wheel group grinding, which has been practical for many years and can ensure the quality of tool production, greatly improving the efficiency of tool production.

3. The front and rear doors are open for unrestricted debugging and maintenance of the machine tool, and the fully enclosed protective cover complies with production safety.

4. All axes are equipped with fully imported servo motors and screw guides, ensuring high precision and resolution, guaranteeing the high production quality and efficiency of the machine tool.

2、 Important components:

1. X axis, horizontal linear CNC axis, servo motor made in Taiwan, China, THK precision ball screw, THK precision roller guide.

2. Y axis, horizontal linear CNC axis, servo motor made in Taiwan, China, THK precision ball screw, THK precision roller guide.

3. Z axis, vertical linear CNC axis, servo motor made in Taiwan, China, THK precision ball screw, THK precision roller guide.

4. A-axis, rotating CNC workpiece axis, servo motor made in Taiwan, China, Japan precision worm gear pair complete set.

5. Add an angle rotation center to the Z-axis column and equip it with an angle encoder to ensure repeated positioning accuracy when changing different thread angles. When changing dimensions, adjusting the machine is more efficient, convenient, and accurate.

6. Whole marble bed frame.

7. Sealed hood for easy machine adjustment and baking paint. The machine can be disassembled as a whole for easy maintenance.

8. The CNC control panel is installed on the hood and is easy to operate with a movable handwheel with a magnet.

9. A dedicated high-speed slotted electric spindle that can be installed with one to three grinding wheels and can be disassembled as a whole to be used in a grinding wheel dressing machine for grinding wheel maintenance.

10. Taiwan, China's high-precision direct connected motorized spindle is used for the side edge and vertical.

11. Variable frequency speed regulation of spindle motor.

12. Install tube sealed oil proof fluorescent lamps inside the machine.

13. Japan's Fujitsu has an automatic loading and unloading mechanism for robots installed outside the machine, which increases the service life of the robots.(Optional)

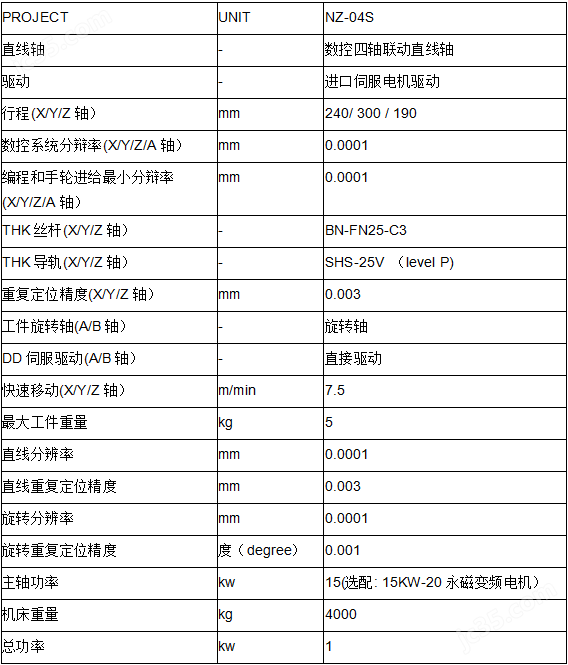

3、 Technical parameters: