-

E-mail

qddetianrun@163.com

-

Phone

18116296609

-

Address

1605, Building A, Liancheng International, No. 758 Jingqi Road, Huaiyin District, Jinan City, Shandong Province

Qingdao Detianrun Electromechanical Technology Co., Ltd

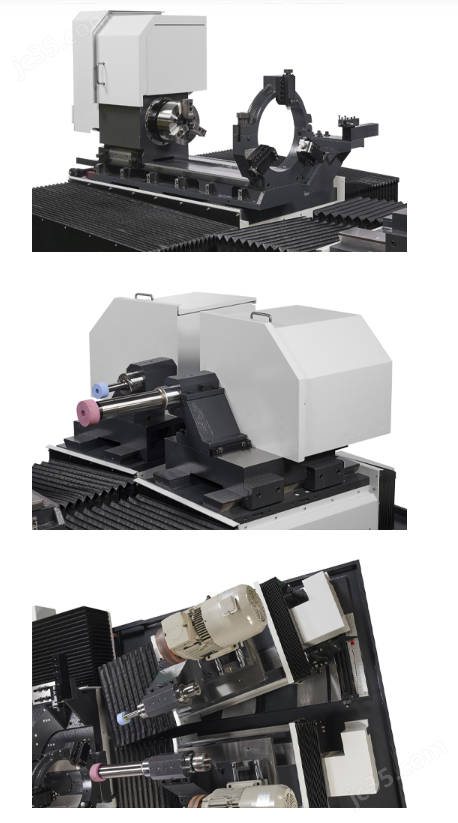

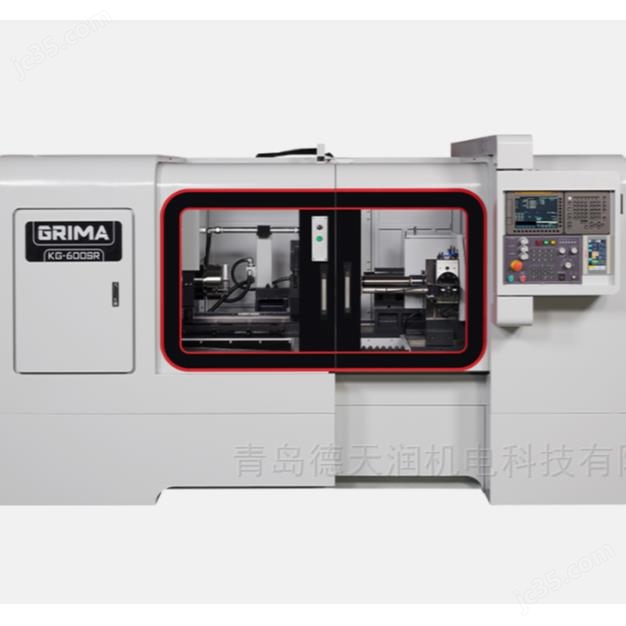

Center frame internal cylindrical grinder

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

KG-600SR

Center frame internal cylindrical grinder

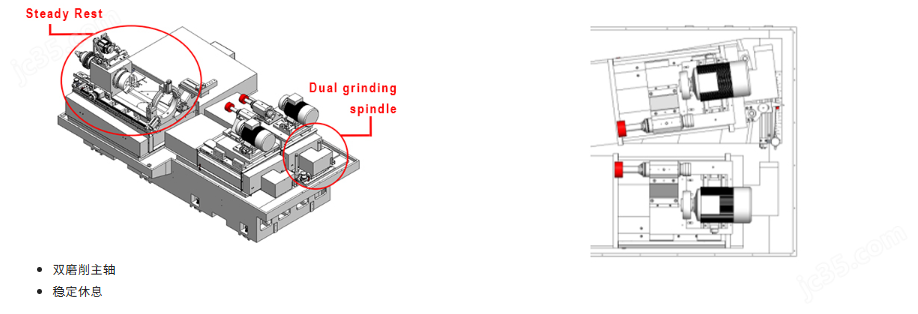

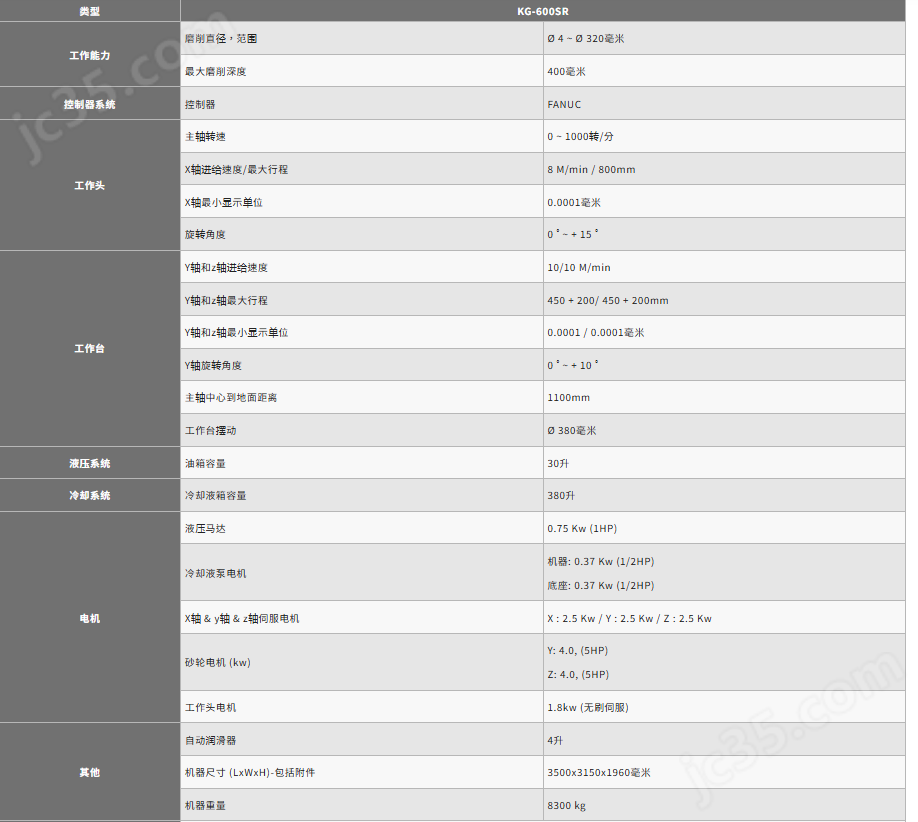

KG-600SRCenter frame internal cylindrical grinderThe characteristics of the model and the central frame component are dual grinding wheel spindles, which can grind workpieces to a depth of up to 400mm. It is equipped with a tailstock manual slider with an air cushion design, allowing the slider position to be adjusted according to the length of the workpiece. In addition, it provides independent angle adjustment of the y-axis to adapt to different cone angles during the grinding process.

X-axis

● Rigid roller linear mode, with four linear modes and 12 blocks to ensure axial stiffness and stability.

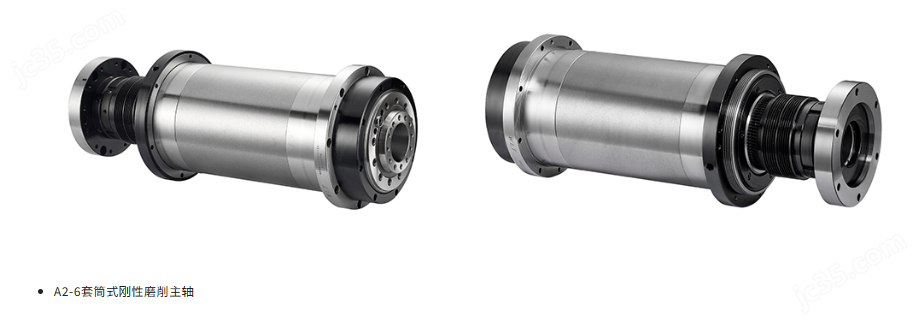

● High rigidity A2-6 taper spindle. This spindle provides excellent radial stiffness, stable thermal minimum thermal deformation, and high dynamic accuracy to ensure absolute grinding quality.

● Air floating sliding design, easy to move the working head along the length of the workbench.

Stable rest, suitable for long workbenches, and provides stability during the grinding process.

Y and Z axes

●The diameter of the belt grinding spindle is 90mm.

●It can be converted to different speeds, greatly improving the cutting efficiency of various workpieces.

●Designed with air floating sliding method, it is easy to adjust the position according to needs.

Y-axis

● Reflection from customers, technological innovation from the past.

●In the past, standard taper grinding involved simultaneous movement of two axes, and long-term use could cause the ball screw to rub and lose accuracy.

●In order to provide customers with ideal solutions, we have innovated an independent y-axis angle adjustment system to ensure the stability and accuracy of taper grinding.