-

E-mail

18936952975@163.com

-

Phone

19352696688

-

Address

No. 9 Kechuang Road, Sucheng Economic Development Zone, Suqian City

Jonuc CNC Equipment (Jiangsu) Co., Ltd

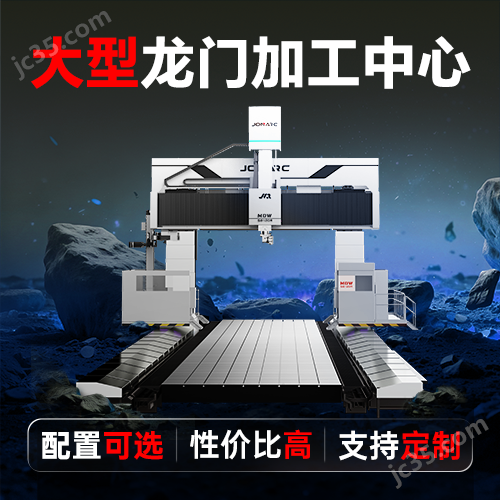

CNC large milling gantry machining center

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

CNC large milling gantry machining center

The width of the fixed beam movable platform gantry is available in 3.3 meters, 3.8 meters, and 4.3 meters

The workbench length is available in 5 meters, 6 meters, 8 meters, 10 meters, and 12 meters

The width of the fixed beam dynamic column gantry is available in 4.8 meters, 5.8 meters, and 6.8 meters

The workbench length is available in 8 meters, 10 meters, 12 meters, and 16 meters

The width of the gantry on the moving beam and platform is available in 3.8 meters, 4.8 meters, and 5.2 meters

The workbench length is available in 8 meters, 10 meters, 12 meters, and 16 meters

The width of the dynamic beam and column gantry is available in 4.8 meters, 5.8 meters, and 6.8 meters

The workbench length is available in 8 meters, 10 meters, 12 meters, and 16 meters

The five axis gantry width of the elevated bridge is available in 3.5 meters, 4.2 meters, and 5.2 meters

The workbench length is available in 4 meters, 5 meters, and 6 meters

The above parameter configurations are all standard models, and can also be freely customized according to customer needs

More models, technical parameters, and configuration plans for large-scale gantry machining centers;

Please clickLarge gantry machining centerList page to learn more about this series of models;

If you want to view other types of gantry machining centers such as fixed beam, dynamic column, dynamic beam, and elevated bridge type;

Please clickLongmen machining centerEquipment classification page, where you can browse all models for more efficient selection!

CNC large milling gantry machining centerProduct Advantage Introduction

1、 Open structure, efficient operating space

The large gantry machining center of Jonuc adopts an open or semi protective structure design, fully meeting the requirements of large workpiece loading and unloading and lifting operations.

The machine tool is equipped with detachable protective devices and safety guardrails, which effectively improve operational safety and processing efficiency while ensuring visibility and convenience.

2、 High rigidity structure, stable support for heavy cutting

The whole machine adopts fixed beam, dynamic column or dynamic beam structure, combined with ultra wide span gantry frame design, with overall balanced force and strong rigidity.

The main castings of the bed, columns, beams, etc. are all made of high-strength cast iron, which has undergone two tempering and vibration aging treatments to eliminate internal stress.

Through finite element simulation analysis, the structure is dynamically optimized to maintain high rigidity, low vibration, and excellent torsional performance of the equipment under heavy cutting and high torque conditions.

3、 Flexible configuration to meet the needs of multiple working conditions

Jonuc's large gantry machining center features highly modular designIt can be flexibly customized according to different processing scenarios and customer process requirements.

Numerical Control System:Optional mainstream brands such as Fanuc and Siemens;

Spindle system:Provide various drive structures such as direct coupling, gearbox, and electric spindle, balancing high-speed precision machining and heavy cutting capabilities;

Sliding pillow structure:Supports three forms of Z-axis 4-wire rail, fully enclosed square slider, and T-shaped slider to meet different rigidity and precision requirements;

4、 Full process control, stable and reliable accuracy

Jonuc has established a comprehensive manufacturing and testing system, achieving full process quality traceability from design to assembly

Processing stage:The core parts are processed by Japanese Okuma, Taiwan, China Doosan and other master machines, and the whole process of key dimensions are monitored by data;

Assembly stage:Strictly implement torque standards, geometric accuracy calibration, assembly positioning, and dynamic balance testing to ensure stability;

Detection stage:Use laser interferometer, ball bar instrument, coordinate measuring machine and long-term load cutting system to test the accuracy and dynamic performance item by item.

Each machine tool undergoes multiple rounds of trial cutting and durability testing to ensure "qualification upon startup and stability upon production".

5、 Widely applicable, achieving both accuracy and efficiency

Jonuc's large-scale gantry machining centers are widely used in industries such as mold manufacturing, aerospace, rail transportation, shipbuilding, energy equipment, and engineering machinery.

Support multiple machining methods such as milling, drilling, boring, tapping, reaming, and reaming, balancing powerful cutting and precision forming.

The X-axis stroke can reach 60 meters, and the Y-axis stroke can reach 12 meters, with the ability to clamp and process oversized workpieces in one go.

6、 Jonuc Manufacturing Strength, Serving the Whole Life Cycle

Jonuc CNC covers an area of 230 acres and has a modern factory building of 150000 square meters. It has core workshops such as constant temperature machining, precision assembly, electrical integration, sheet metal spraying, and quality inspection center, with an annual output of 500 gantry machinesmachine toolManufacturing capability.

The company has more than 20 after-sales service outlets nationwide, providing full lifecycle support such as remote diagnosis, precision calibration, function expansion, and preventive maintenance