-

E-mail

runfine.filter@163.com

-

Phone

13515452159

-

Address

Zhifu District, Yantai City

- Copper wire drawing filter, non-woven filter paper for water tank

- Flat bed filtration system with matching filter paper

- magnetic coolant separator

- Paper tape filtering system

- Specialized machine tool filter water tank

- Paper tape filter

- Drum type paper tape quenching liquid filtration device

- Skimmer belt

- Magnetic filter machine

- Online filtering device for machine tool coolant

Yantai Yunfan Filtration System Co., Ltd

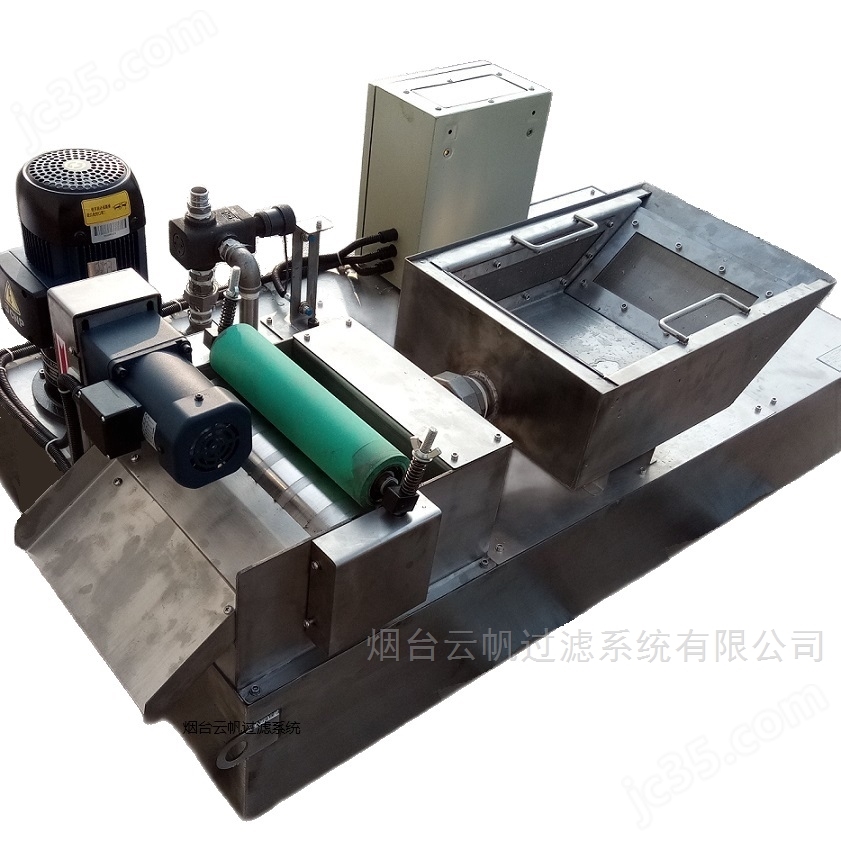

Burr polishing machine emulsion circulation filtration water tank

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

The metal particles and sand particles cut by grinding machines and other machine tools during processing fall into the cooling box together with the coolant,The supply pump sends the coolant from the tank to the processing site again. If there is no impurity separation and treatment device,Impurities will fall on the processed parts.

The use of magnetic separators can effectively solve the above problems. In production practice, magnetic separators are often used in conjunction with water tanks because they occupy small space, are easy to install, and can adsorb impurities reliably and conveniently. They can effectively adsorb impurities such as iron powder in the liquid, reduce the precipitation of impurities in the water tank, and extend the cleaning cycle of the water tank. The combination of magnetic separator and water tank can effectively reduce the labor intensity of cleaning sediment impurities in the water tank compared to using a sedimentation water tank alone, and the procurement cost of magnetic separator is not high.

The magnetic separator automatically absorbs and discharges slag without the need for manual intervention.

Magnetic separators can be combined with bag filters, filter cartridge filters, etc. to filter out non-magnetic sand particles and other impurities, improving filtration accuracy. When used in conjunction with a belt skimmer, it can effectively remove floating oil from the liquid surface.

Burr polishing machine emulsion circulation filtration water tankThe details are as follows:

Magnetic separator1The platform, modelRFCF25Meet the traffic demand25Rising per minute, magnetic cylinder with strong magnetism, shell made of carbon steel material, painted treatment.

water tank1The platform, appearance1000*1000*220Millimeter, bracket1Set, made of carbon steel material, spray painted.

vertical pump1The platform, traffic0.5Cubic per hour, head11.5Rice.

Horizontal water pump1The platform, traffic1.5Cubic per hour, head10rice

Filter cartridge filter1Set, processing capacity100Increase per minute, accuracy10micron

level gauge2set

Pipeline fittings and valves1set

Burr polishing machine emulsion circulation filtration water tankMake according to the requirements.

The details and technical requirements for the filtration water tank of the rolling machine cooling system are as follows:

Model of machine tool filter water tankRF-100, handle traffic100Raise every minute.

water tank1Set, with a capacity of approximately350L, made of carbon steel material, spray painted, with hanging rings at all four corners, and a water tank cover plate with a water inlet.

Rubber roller type magnetic separator1Platform, modelRFCF100Processing capacity100Raise every minute.

circulating water pump1Platform, modelAB100, traffic100Lift per minute, head4Rice.

Belt skimmer1Platform, modelRFDP40The oil skimmer is equipped with an oil-water separation box and an oil receiving box for easy recovery of oil products.

Water level control sensor1Set.