-

E-mail

wq_zhineng@163.com

-

Phone

13661320916

-

Address

No. 55 Shangxin Road, Wuzhong District, Suzhou City, Jiangsu Province

Woqi Intelligent Equipment (Suzhou) Co., Ltd

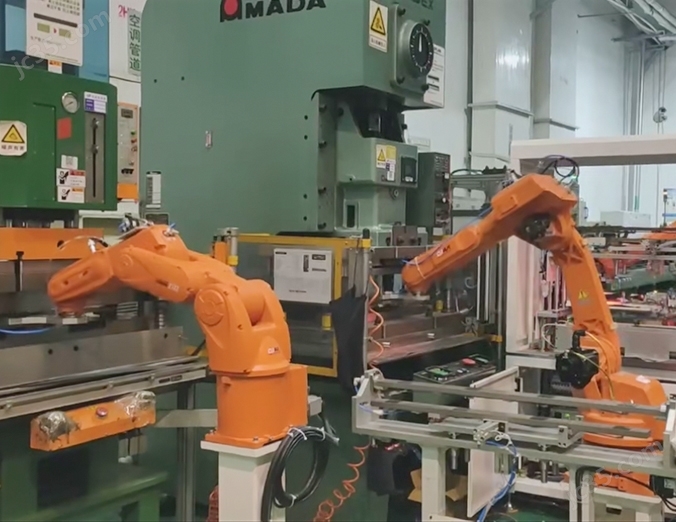

Battery positive and negative electrode shearing automation unit

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Battery positive and negative electrode shearing automation unitIt is an efficient and precise device used for positive and negative electrode shearing in the battery production process. This unit is capable of automatically completing cutting tasks, greatly improving production efficiency and quality.

This automation unit adopts excellent mechanical design and control technology, with high accuracy and stability. Its main components include feeding system, shearing system, positioning system, and control system.

The feeding system is responsible for transporting the positive and negative electrodes of the battery to be cut to the cutting area, ensuring the continuity and smoothness of the entire operation process. The cutting system is equipped with high-performance cutting tools that can achieve precise cutting operations, ensuring the integrity and consistency of the positive and negative poles.

The positioning system uses precise sensors and image processing technology to automatically identify and locate the battery to be cut, ensuring the accuracy and consistency of each cut. The control system is responsible for the operation and coordination of the entire automation unit, achieving fully automatic cutting operations, and can set and monitor parameters through the human-machine interface.

This automation unit has multiple advantages. Firstly, automated operations have replaced traditional manual cutting, greatly reducing the complexity and errors of manual operations and improving production efficiency. Secondly, precise cutting operations ensure the integrity and consistency of the positive and negative electrodes of the battery, ensuring product quality and safety. Again, the high stability and reliability of the automation unit enable it to operate for a long time without causing malfunctions or shutdowns, reducing maintenance costs and production risks.

Battery positive and negative electrode shearing automation unitIt has broad application prospects in the field of battery production. Both traditional battery manufacturing enterprises and emerging power battery manufacturing enterprises can improve production efficiency and product quality, reduce production costs and risks by introducing this automation unit. At the same time, the device can also be customized according to customer needs to meet battery cutting tasks of different specifications and requirements.

In summary, it is an efficient and precise device that provides a reliable solution for cutting operations in battery production processes. Its introduction will bring significant benefits and competitive advantages to battery production enterprises.