-

E-mail

18661876701@163.com

-

Phone

18661876701

-

Address

120 Shixin North Road, Xiaoshan Economic and Technological Development Zone, Xiaoshan District, Hangzhou City, Zhejiang Province

Youjia International CNC Machine Tool Co., Ltd

Youjia Group - Leader in Automotive Manufacturing Solutions

Date: 2025-09-17Read: 6

01 Automotive Manufacturing

AUTOMOTIVE MANUFACTURING

As a convenient and efficient means of transportation, cars are an important carrier that supports the pace of modern human life and expands the boundaries of life.

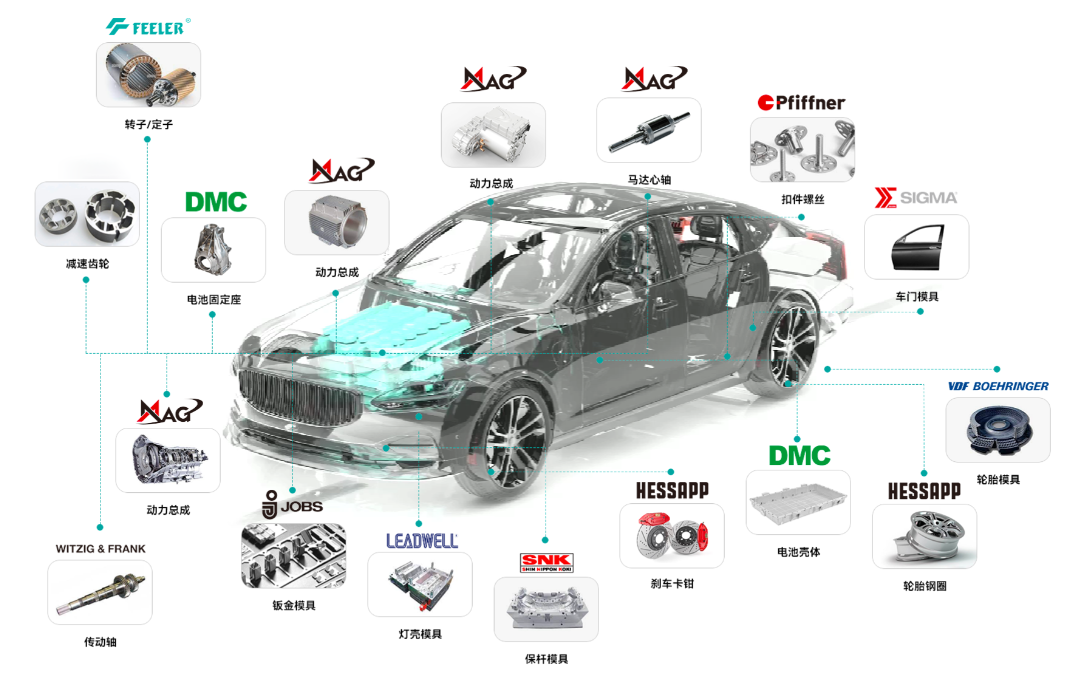

Automobiles are composed of numerous key system components such as engines, transmissions, and brakes, and machine tools are the core equipment for processing these components. High precision machine tools are required to ensure machining accuracy and quality, such as engine cylinder blocks and transmission gears. Numerical control machine tools are indispensable "industrial mother machines" in automobile manufacturing.

Youjia Group has been deeply involved in the automotive industry for many years, supported by technological innovation, providing automotive manufacturing enterprises with comprehensive solutions ranging from processing technology, process design, manufacturing system configuration planning, to turnkey solutions for the entire automotive industry manufacturing system. With a mature technological system and rich practical experience, helping car companies achieve cost reduction, efficiency improvement, and upgrading development.

02 Customer Cases

CUSTOMER CASES

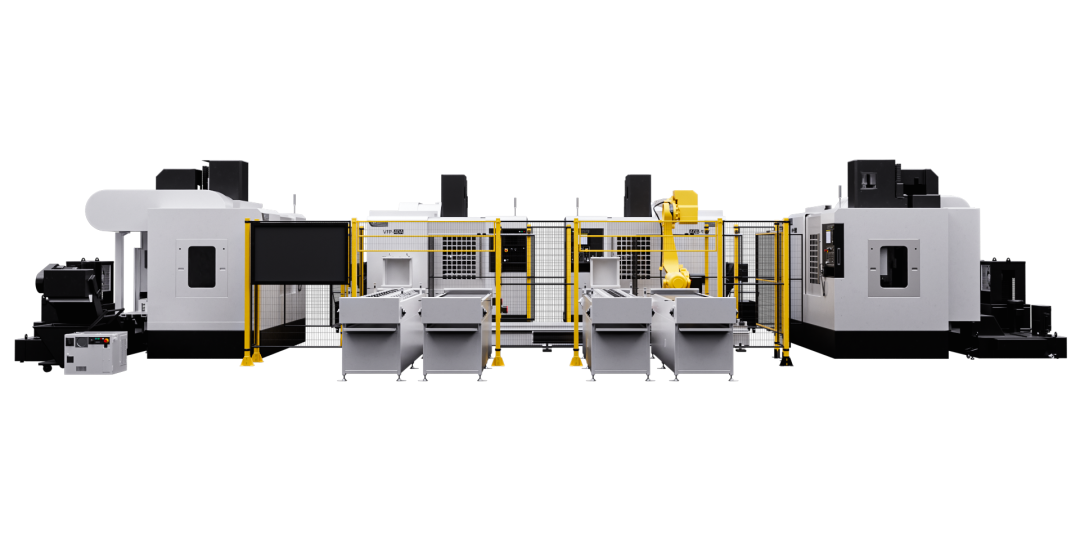

FEELER steering knuckle automation solution

The steering knuckle is one of the core components of a car, and it is a key connecting component between the car's steering system and suspension system. It directly affects the steering handling and driving safety of the car, and plays an important role in transmitting steering force, carrying the weight of the car body, and stabilizing the wheel posture during the whole vehicle driving process.

Highlights of the production line

The core equipment FEELER vertical comprehensive machining center VFP-40A adopts a high rigidity casting structure and a herringbone column design, with Z-axis hard rails to ensure machining stability.

Its arm type tool changing system (ATC) ensures efficient and precise tool changing. Equipped with R-30iB/R-30iB Mate controller, it has high performance, fast response, and strong safety performance. FANUC six axis robot collaborates with ground rails to achieve automatic loading and unloading processes, with flexible movements and precise positioning.

The specially designed claw adopts an internal support clamping method, and the contact part is designed with a serrated pattern, effectively preventing the workpiece from falling off and ensuring the stability of the processing process.

The feeding bin has an intelligent shortage warning function, and the discharging bin realizes automatic conveying.

Full coverage of safety facilities such as door locks and guardrails ensures a safe and reliable production environment.