-

E-mail

mandy.ding@grinding.cn

- Phone

-

Address

No. 1128 Taishun Road, Anting Town, Jiading District, Shanghai

Unitech Grinding Machinery (Shanghai) Co., Ltd

WALTER G 200 blade automation solution: allowing complex blade batch processing to be completed in one go

Date: 2025-10-10Read: 4

G 200 blade automation solution

In the field of tool manufacturing, poor consistency in mass production, difficult control of clamping accuracy, and high dependence on manpower have always been bottlenecks that restrict the improvement of production efficiency and blade quality. How to achieve high-precision, fully automatic, and customizable blade processing? The HELITRONIC G 200 blade automation solution launched by WALTER provides innovative answers with compact layout, intelligent system, and modular design.

1、 Not just automation,

It is also a reconstruction of the "smart manufacturing closed-loop"

The WALTER HELITRONIC G 200 blade automation solution constructs a complete high-precision intelligent machining unit from clamping, material changing, grinding to detection. Its innovation is not only reflected in hardware integration, but also in systematic collaboration and response capabilities:

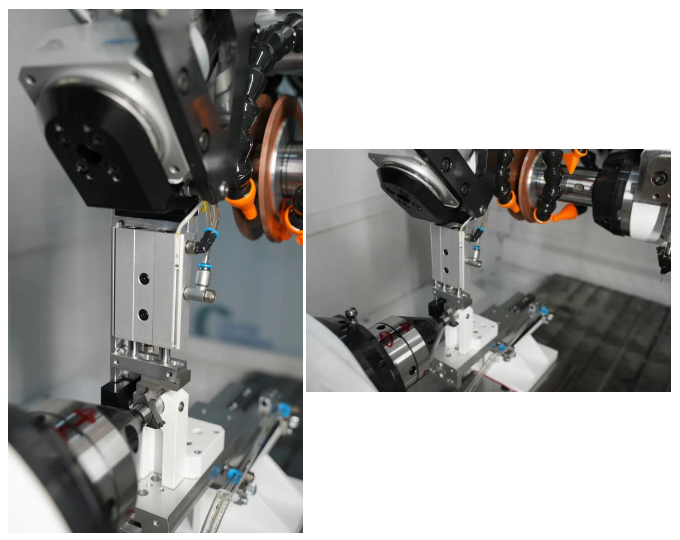

01 Customized Fixture System: Balancing Rigidity and Accuracy

By using professional clamping technology and specially designed stud structures, combined with independently designed automated fixture devices, micro level positioning and high rigidity fixation of different blades are achieved, suppressing machining vibration from the root and ensuring machining stability and accuracy.

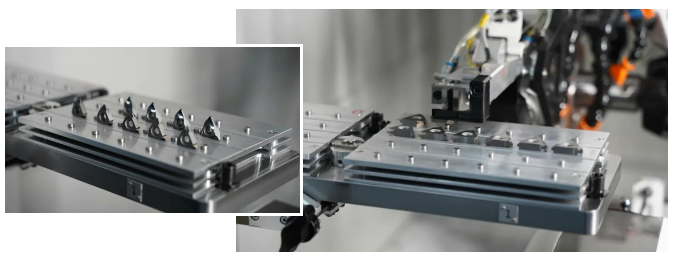

02 Flexible loading and unloading system: suitable for both small and large batches

Both the robotic arm and the material tray can be customized according to the blade processing requirements, supporting fast switching between multiple varieties and small batches, and also suitable for large-scale continuous production. The positioning device ensures that the blade is calibrated before installation to prevent human error. While improving efficiency, it lays the foundation for achieving unmanned and automated continuous production.

03 Dual spindle design: unlimited expansion of machining capabilities

HELITRONIC G 200 has two spindle ends, a dual belt driven spindle, and can be equipped with up to 8 grinding wheels. It can achieve seamless connection between various machining processes such as rough grinding and fine grinding, greatly improving equipment utilization.

2、 Technological advantages are not just highlights,

It is also a guarantee for stable output

The HELITRONIC G 200 embodies WALTER's profound technical expertise in terms of structure, control, and software.

01 Low vibration mineral casting bed body+ultra short axis stroke design

The G 200 adopts a mineral casting bed body, which has excellent vibration suppression performance and thermal stability. It is matched with a compact shaft layout and ultra short shaft stroke design to ensure continuous and controllable dynamic accuracy during the grinding process.

02

FANUC CNC system+

HELITRONIC TOOL STUDIO software ecosystem

The ergonomic design and the integrated multifunctional touchpad with a 21.5-inch screen that can swing simplify operation and better adapt to the workspace. Equipped with FANUC control system and TOOL STUDIO software system, the operation response is fast and the interface is friendly. Combined with modular programming and 3D simulation functions, it achieves "what you see is what you get" grinding processing, greatly reducing the operating threshold.

03 Machine Tool Reference Point Electrification Automatic Measurement (AEMDM)

By using electric contact to accurately position the axis, the electrical measurement of the machine tool reference point can be achieved, improving the efficiency of setting and processing consistency. Compared with manual measurement methods, it significantly saves time in automatic operation and eliminates errors caused by human factors.

3、 From small blades to large markets:

Widely adapt to customer needs

Wide range of blade applications: The G 200 blade automation solution meets the automation grinding and production of common milling and turning blades, and can be applied to high-precision blade grinding and processing in fields such as automotive parts, aviation parts, mold manufacturing, oil pipelines, and general machinery.

The WALTER HELITRONIC G 200, occupying less than one office desk, redefines the "complete blade production line for compact workshops" by integrating high rigidity structures, intelligent control systems, and fully automatic loading and unloading solutions. It not only solves the pain points of accuracy and efficiency, but also becomes a key engine in the intelligent upgrade of cutting tools with the advantages of customization, easy maintenance, and high integration.

Accuracy is a fundamental skill, automation is a must answer question, and intelligence is the future competitiveness. Welcome to join hands with WALTER and use the HELITRONIC G 200 blade automation solution to push your blade production to a new stage of higher efficiency, stability, and sustainability.