-

E-mail

mandy.ding@grinding.cn

- Phone

-

Address

No. 1128 Taishun Road, Anting Town, Jiading District, Shanghai

Unitech Grinding Machinery (Shanghai) Co., Ltd

Say goodbye to the bottleneck of traditional grinding! How to create a high-precision PCD reamer with STUDER KC33?

Date: 2025-11-27Read: 6

1. Insight into the problem

We have worked on many clients' production sites,

I have heard of such a typical problem:

PCD reamer, good is good, but it's too 'delicate'! When grinding, the cutting edge will collapse at will, and the precision will run at will

Behind this, it is often not a matter of tool material, but rather the comprehensive ability of the grinding system failing to match the high requirements of PCD reamer material. This precisely reflects the fundamental contradiction between traditional grinding thinking and the characteristics of superhard materials.

2 Innovative Applications

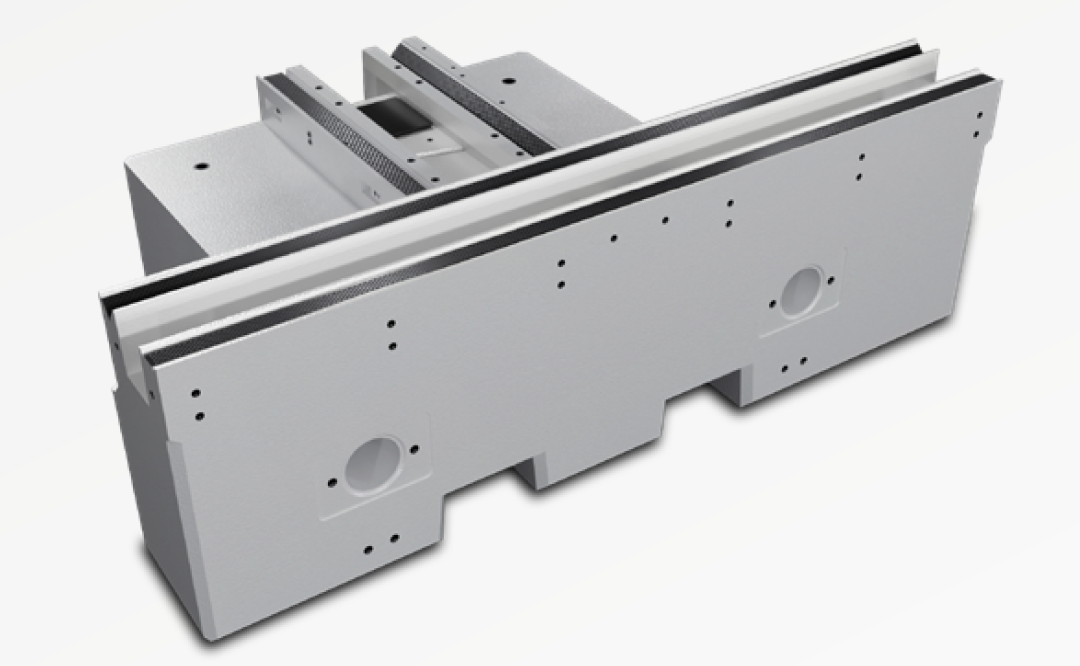

To systematically address this challenge, United Grinding China has innovatively constructed a complete grinding application solution for PCD material reamers on the STUDER KC33 CNC universal internal and external cylindrical grinder based on tool material characteristics and machining accuracy assurance.

It is worth mentioning that it does not simply treat PCD reamers as a machining object, but rather transforms them into a stable and efficient precision manufacturing process by systematically analyzing material properties and fully tapping into the potential of the grinder.

1、 Typical challenges from the field

Processing difficulties

In aerospace, automotive engineering, medical and other fields, PCD reamers are the key to ensuring the final hole accuracy and quality of parts. We all know that PCD cutting tools are made of superhard materials, with high requirements for smoothness and accuracy. In addition, their manufacturing process is limited by three major bottlenecks due to the presence of multiple blades or complex groove shapes

1. Uncontrollable process:

The phenomenon of tool breakage occurs randomly, and the yield is like opening a blind box;

2. Difficulty in reaching accuracy limit:

The micrometer level tolerance requirement is a test of the stability and dynamic accuracy of the machine tool;

3. Low overall efficiency:

Highly dependent on the skills of operators, there is enormous pressure on delivery cycles during mass production.

2、 Application analysis:

How to systematically create qualified PCD reamers for KC33

Innovative application

The innovation of STUDER KC33 lies in elevating the grinding of PCD reamers from a simple "machining process" to a complete "process system".

Application One: Redefine "Blade Quality" with "System Rigidity"

Processing PCD reamers is not just about replacing sharper grinding wheels. KC33 is based on GRANITAN ® The ultra stable grinding environment constructed by artificial granite bed can fundamentally suppress the vibration that causes micro breakage of PCD reamers. This is the physical basis for achieving high consistency grinding and the inherent advantage of traditional cast iron bed bodies.

Application 2 redefines "precision commitment" with "real-time closed-loop"

STUDER KC33 features a high-precision head frame (0.0004mm) and a precision fine adjustment cone (0.0001mm) tail frame, as well as a fully automatic B-axis with a division resolution of 1 °, laying the foundation for efficient one-time cutting grinding.

The precision guarantee of KC33 is rooted in its high-quality gray cast iron manufactured longitudinal and transverse sliding tables, fully enclosed protective guide rails, and scales for setting and adjustment. The worktable can rotate 8.5 °, ensuring excellent straightness of 0.0025mm on a grinding measurement length of 650mm. The slide table is driven by a large-diameter ball screw, providing stable and precise feed for the grinding process.

The STUDER KC33 grinding wheel head supports a linear velocity of up to 50m/s and can be optionally equipped with a high-power spindle, ensuring high efficiency and excellent surface integrity when grinding PCD tools.

Application Three Redefines "Production Efficiency" with "Graphization"

Through graphical programming, the process experience of the master is transformed into standardized digital instructions, greatly reducing the manufacturing threshold of precision cutting tools and enabling innovative technologies to be quickly applied.

3、 Practical case:

How KC33 overcomes two types of high difficulty PCD reamers

Case 1:

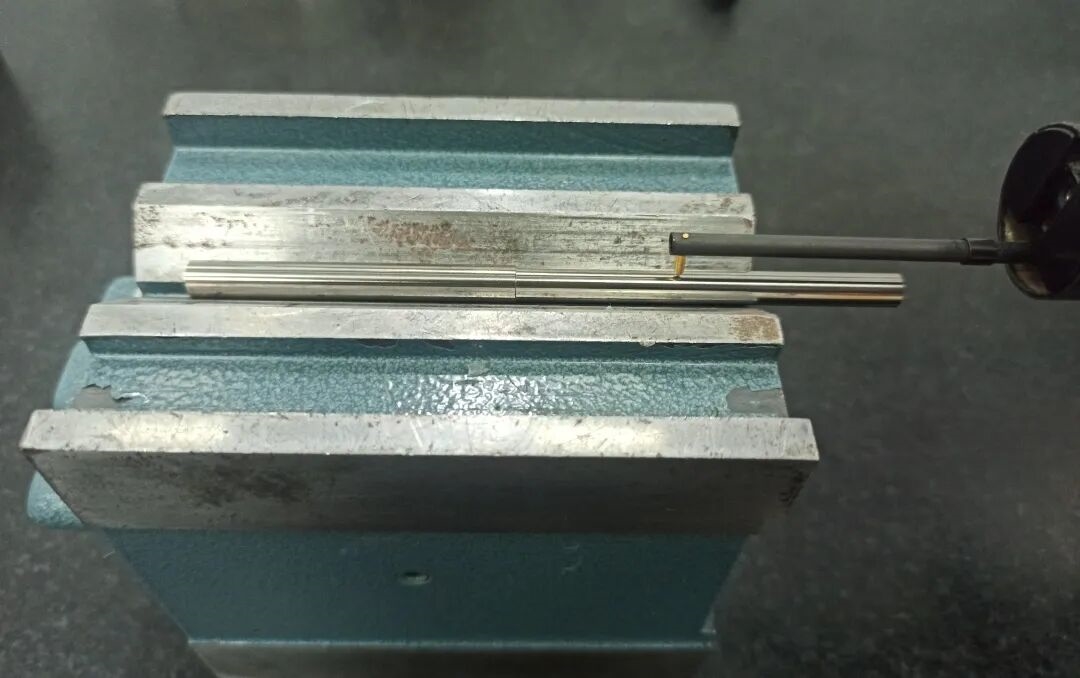

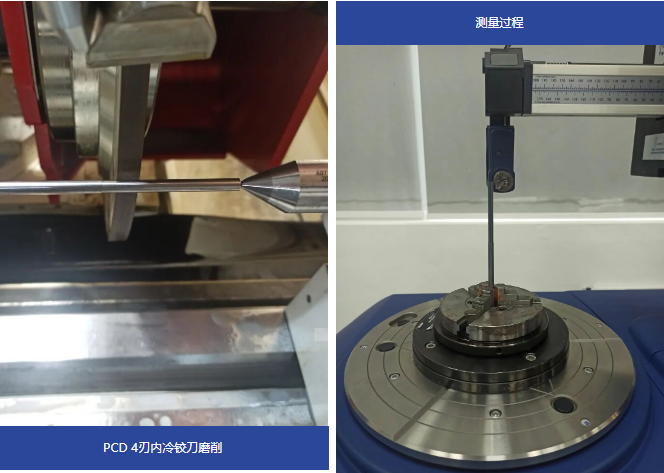

PCD 4-side internal cold reamer (substrate) - a balance between high precision and high efficiency

The reamer is a slender shaft structure (Ø 5.5 × 110, 20 times diameter), with a hard alloy substrate and extremely strict precision requirements (runout, straightness, and cylindricity are all 0.002mm).

1. Core difficulty:

Thin shafts are prone to deformation, diamond grinding wheels are difficult to repair, and accuracy is difficult to ensure.

2 KC33 Solution:

Using customized diamond grinding wheels to ensure grinding efficiency and stability.

Apply the combination dressing strategy of "diamond pen+silicon carbide grinding wheel" to improve the performance of the grinding wheel.

Optimize the rough and fine machining process routes to achieve better machining stability.

3 Application achievements:

We have achieved ultra-high precision of 0.001mm roundness, 0.002mm cylindricity, and 0.002mm straightness, and efficiently ground the remaining 1mm in about 46 minutes, achieving stable production.

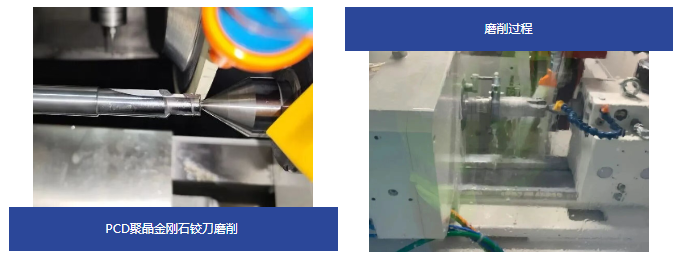

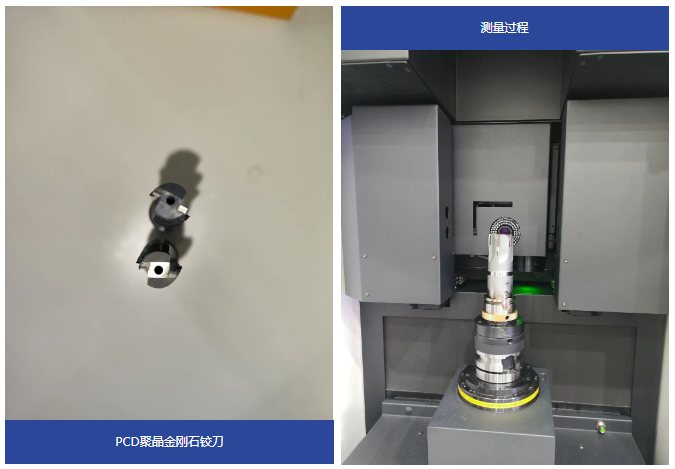

Case 2:

PCD Polycrystalline Diamond Reamer - Challenges of Superhard Materials and Complex Structures

The workpiece requires intermittent grinding, with no chipping at the cutting edge, a conical structure, and a measurement benchmark that is not consistent with the machining benchmark.

1. Core difficulty:

Superhard materials lead to difficulties in grinding, difficulty in controlling blade integrity, and high requirements for benchmark uniformity.

2 KC33 Solution:

Optimize parameters for intermittent grinding to ensure the stability of the grinding wheel during cutting.

By precise path control and trimming processes, the quality of the cutting edge is guaranteed and a stable inverted cone is formed.

Utilizing the high repeatability positioning accuracy of machine tools, unifying machining and measurement benchmarks to ensure batch consistency.

3 Application achievements:

Successfully achieved continuous grinding of qualified workpieces, with a single piece cycle time of about 20-30 minutes, stable control of critical dimensional tolerances within 0.003mm, and no chipping at the cutting edge.

Application significance

The innovative application of STUDER KC33 in the field of PCD reamer grinding lies not in the breakthrough of a single technology, but in the systematic combination of "rigid foundation+intelligent closed-loop+process optimization", transforming a challenging machining process into a reliable and efficient modern manufacturing process.

It not only solves the problem of grinding accuracy, but more importantly, it provides the industry with new ideas and controllable solutions to tackle stubborn challenges such as "slender shaft deformation" and "intermittent grinding of superhard materials". Make even the most complex processing effortless and stable like a mountain.